Other Parts Discussed in Thread: LM5157EVM-SEPIC, LM5158, LM5157

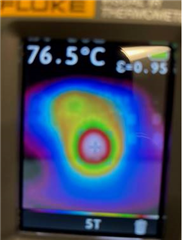

Hello, we are trying to use the LM5158-Q1 in the SEPIC topology to output 25V with a max of 1A. We built a prototype and tested with a half amp load and saw a very quick and large temperature rise. The chip heated up over 75°C in about 1 minute while dissipating this 12.5W.

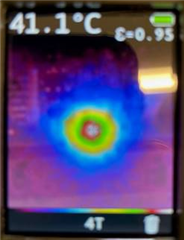

We compared this to the LM5157EVM-SEPIC eval board and saw that after about 15 minutes the temperature was still at only 41.1°C with a 12V, 1A load, so almost 12.5W dissipated.

I know that these aren't the exact same part, but they are similar and the user manual for the eval board says it can be used to evaluate the LM5158-Q1 so I figured it would be similar.

Do you have any suggestions as to why this may be happening?

Thanks