Other Parts Discussed in Thread: EV2400, BQSTUDIO,

Hello TI Team,

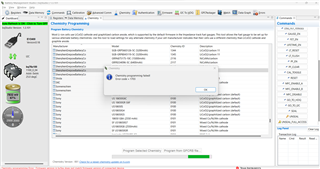

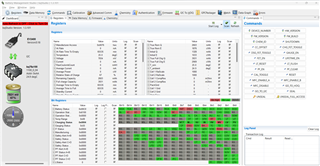

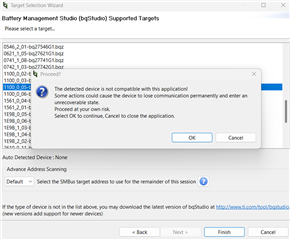

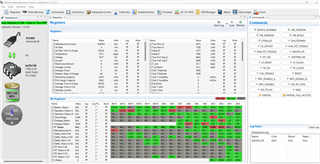

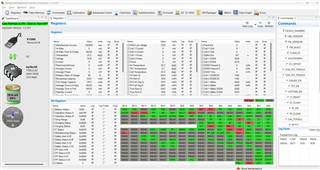

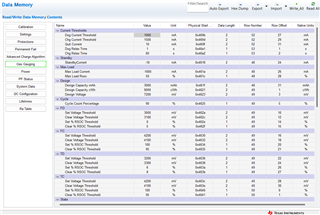

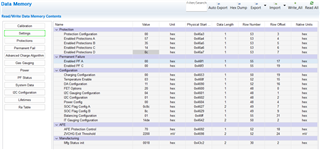

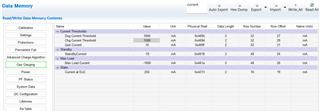

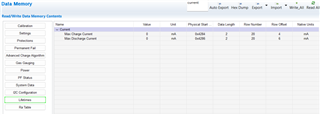

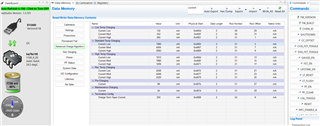

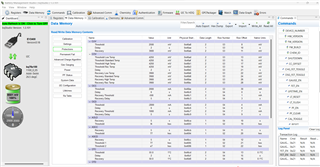

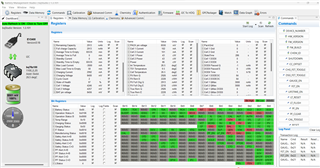

I am struggling to turn on the charging and discharging Mosfets BQ78Z100DRZT,

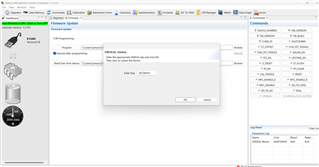

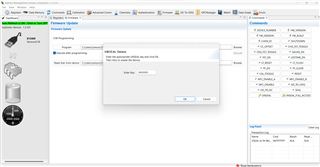

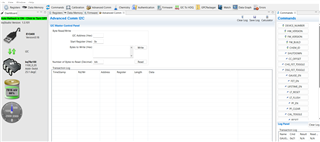

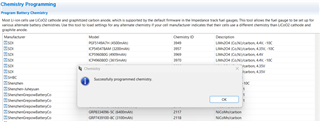

Configure and upload the firmware using the EV2400 Evaluation module.

I have used external Mosfets for balancing the cells.

Battery Details

2000mAh,

2Cell in series,

4.2V DC per cell.

Please find the attached schematic.

BRs

Murthy