Other Parts Discussed in Thread: EV2400, BQSTUDIO, GPCCHEM

Hi,

We are going to be using the BQ34Z100PW-G1 in numerous products at medium production levels. We need it to work with a number of LifePo4 batteries with differing Ahr ratings. I have spent weeks attempting to successfully complete the battery learning cycle with no luck. I urgently need help to resolve this or I am going to be forced to move to an alternative fuel gauge. Can you please answer the following questions:

- Why does BQStudio present a warning saying that the BQ34Z100PW-G1 is not supported? I am using the latest version of BQStudio and the latest firmware in the EV2400.

- What are the CC Offset and Calibration Offset shown in the calibration page of BQStudio? There is no mention of these in the documentation.

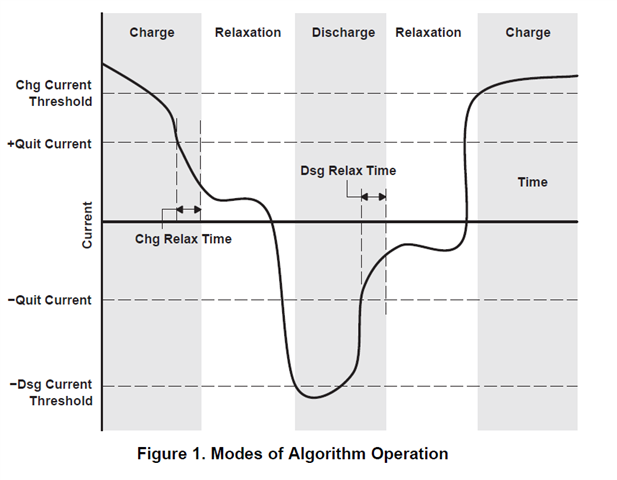

- Is SLUA903 the correct document to be using for the learning cycle? Paragraph 2.5 of this document states "

quit current must be less than the Dsg Current Threshold and Chg Current Threshold." This makes no sense when referencing the charge cycle diagram in the same document (see below).

- The battery datasheet does not provide a value for Charge Term Taper Current. How should I get a value for this?

- Some of our units stop operating with 20% charge still remaining in the battery. Do I only need to discharge to this level for the ChemID log file and for the battery learning process?

- I submitted the attached files to the online ChemID tool. I got an error message saying no discharge cycle found, even though there is a "current" column containing negative values.

- I used the BQStudio logger to record the log file for the ChemID tool. Was that the correct tool to use?

Would it be possible to get some help with the battery learning process?

Many thanks for your help,

Adrian Hallas

Research & Development Lead

BLE Lighting & Power Ltd

ProcessingType = 2 NumCellSeries = 1 ElapsedTimeColumn=1 VoltageColumn = 2 CurrentColumn = 3 TemperatureColumn = 4