Other Parts Discussed in Thread: ALLIGATOR, , TPS40210

Hi Team,

We would like to ask your help regarding our customer's inquiry below.

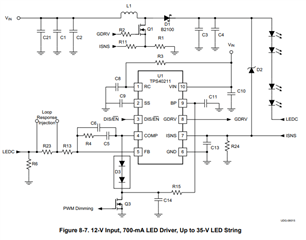

I went and built the circuit in Figure 8-7. I forgot to add the high-side resistor on the gate for the PWM input. I wanted a separate PWM input that customers can use. Should the high side resistor connect to BP or Vin?

I also forgot about the high side resistor and wondered on the "weird" behavior a bit. After figuring out the issue I connected a 3.3V battery(LiPo with low energy left) to + side of PWM and - to supply ground using alligator clips. I am using a benchtop power supply to power the thing and it behaves strangely. The power supply shows the circuit using only ~250mA at 12V, when I set the resistor to 0.5 ohm which means it should use at least that since it's a boost driver.

So I took a function generator and fed square waves to the PWM + input and connected - to supply ground again. The LED flashes under 95% duty cycle with 4V and 10KHz but at 100% the power supply shows it's using the expected >500mA.

Why do you suppose it is flashing? Also with the PWM input floating, with Vin of 5V it gets bright and pulls high amount of current, heating up the inductor significantly. The datasheet says that when the Vin is under 8V, BP is also under 8V.

I am thinking it's a various combination of quick and dirty alligator clips which picks up ambient noise and the Vin itself being dirty? It's a linear power supply but it's being powered by the inverter.

Regards,

Danilo