Hi all,

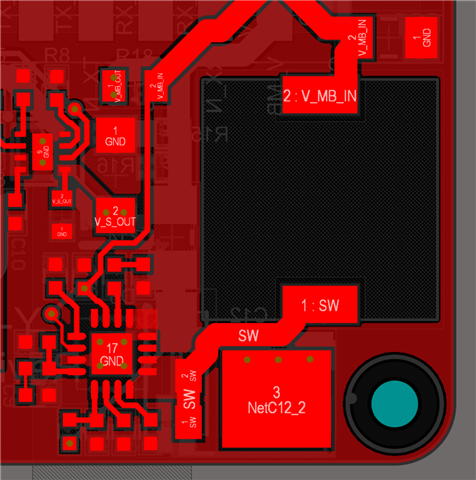

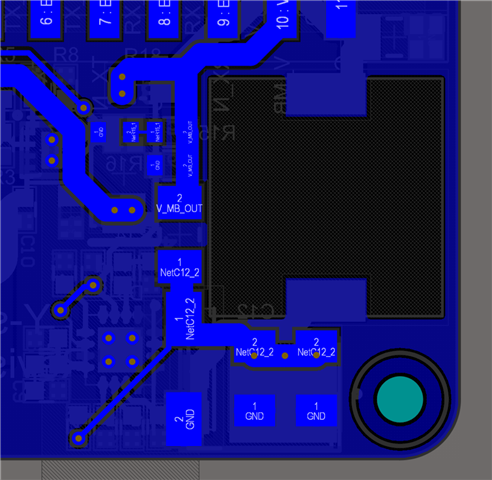

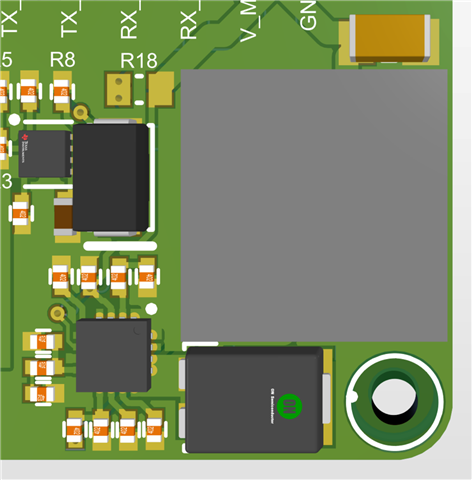

I am using the LM5157 in a 12V/24V, 2A design. Below is the schematic:

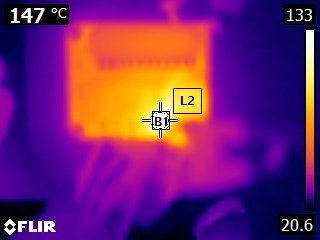

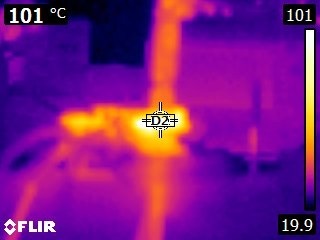

At I_LOAD above 1.5A, the design becomes unstable in about 90 sec: the output starts glitching, before dropping to ~12V. The output and SS waveforms after the instability event are attached below:

Double checking with WEBENCH, I changed R9 to the recommended value of 1K. This improved the situation, however it still became unstable after 5 min. Changing C17 to 10nF (recommended value) worsened the performance and it became unstable after 3 min.

I am not sure of the consumption profile of the load and doubt that it will draw 1.5A or even 2A constantly, however I would like to improve the robustness of the design.

Any advice would be much appreciated.

Regards,

Boris