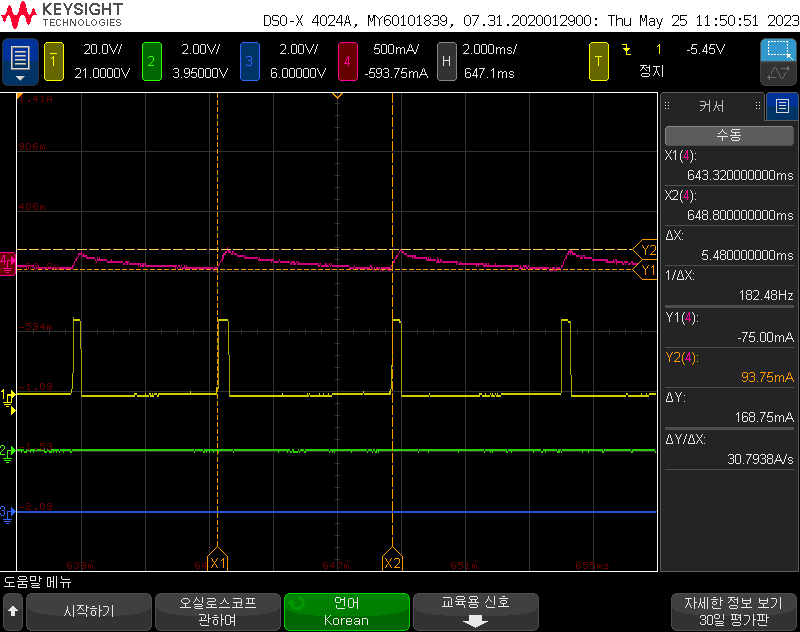

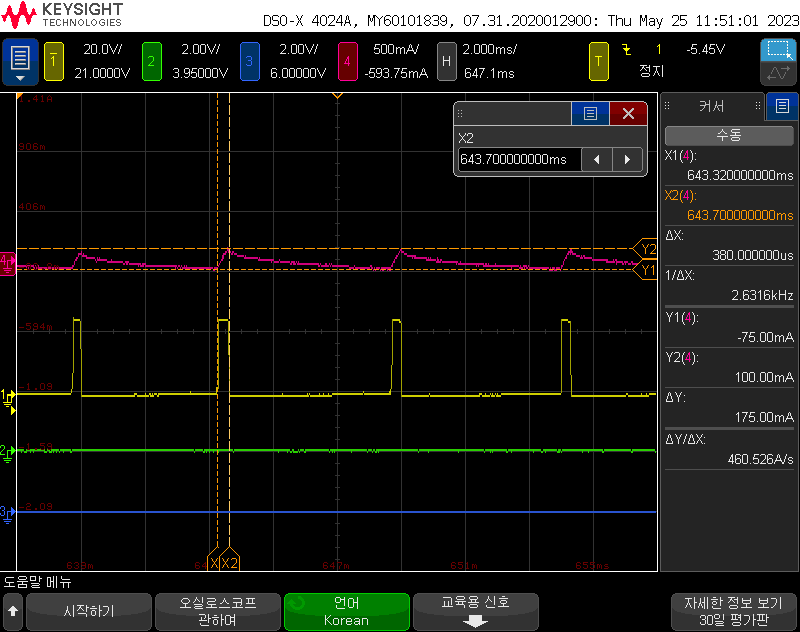

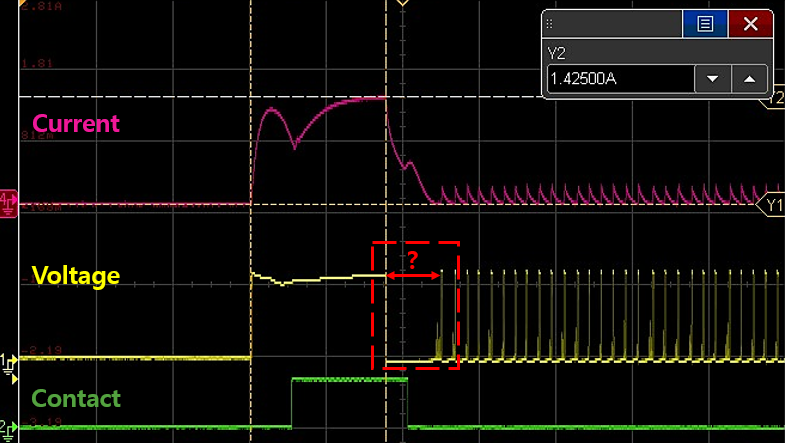

"I designed a circuit using DRV 103 to drive a DC solenoid and conducted tests. However, the PWM frequency is not outputting the desired value, and the solenoid coil current becomes 0 at the moment it turns on. Does the current control always have to be set to 0 for it to reset? Or is there a way to drive PWM regardless of the coil current? Please confirm.

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.