Other Parts Discussed in Thread: TL431

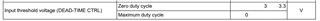

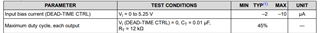

Datasheet P6 is described maximum duty cycle at typ.

Is there min and max value for maximum duty cycle.

Also, please let me know variation in the case of 90% duty cycle (DTC: GND, OUTPUT CTRL: GND).

【Background】

I investigating the reason for become 85% duty cycle, not so target of 90% on boost application.

I have listing up other possible causes(Inductor, accuracy of external, etc), but I would like to confirm the Min~Max range in the maximum Duty cycle, too.

Best regards,

Satoshi