Hi,

We have an electronic board in production with the BQ24650 for a maximum charge current of 4A (using a 6.8uH inductor and 10 milliohm sensing resistance).

This board works perfectly, with excellent performance and reaches the maximum charge current of 4A.

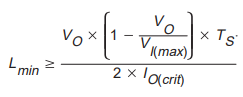

We are starting a new project where the maximum chargecurrent will not exceed 750mA, so it would be appropriate to use a 15uH inductor and 40 milliohm resistor for the maximum load current of 1A.

The disadvantage of this solution is that we have to stock more components to manufacture both board models.

So the question is what is the tradeoff of using the charger designed for 4A charging, when we know that the charging current will never exceed 750mA.

Will there be efficiency reduction or is it similar?

What is the tradeoff of the solution we describe ?

I thank you in advance for your comments.

regards

Jose