Hi Team,

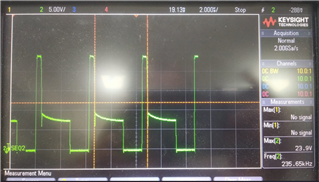

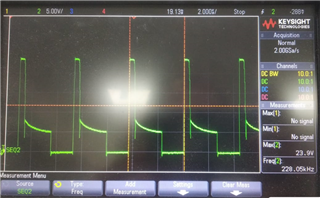

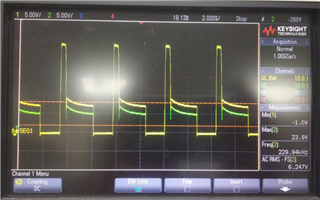

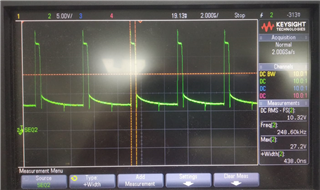

We have the Buck converter prototype board using LM5176, input voltage 24V and output 5V. while power ON the board we got the 5V output voltage without connecting any load .

But we have noticed that first MOSFET Q1 getting heating up and 24V input side drawing current almost 250mA.

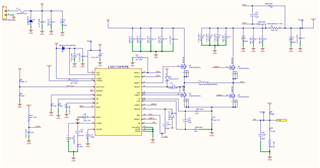

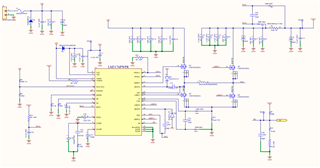

Kindly find the below picture of reference schematic and let us know any update required in schematic or your suggestion to solve this issue.