Other Parts Discussed in Thread: OPA192

Hi all

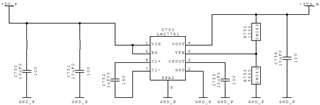

We are testing prototypes with LM27761. Input 5V, Output -3.5V with about 1-10mA to supply negative rail for opamp OPA192. Minimum required is -3.4V, maximum is not critical and even -5V are ok.

During thermal and humidity tests we found that output supply voltage drops and does not give the required output of -3.5V. It drops even below -2.5V @ -40degree Celsius.

We use Feedback Resistors R1=120k / R2=56k and found that these high values are sensitive to humidity. We would like to use 10x smaller resistors but Datasheet requires minimum 50k for R2.

Plan is to use R1=10k / R2=5.6k to make the system less sensitive to humidity, but that is violating the Datasheet value of minimum 50k.

Any technical reason for the minimum 50k requirement?