Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO, BQ34Z100

Hi,

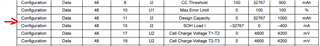

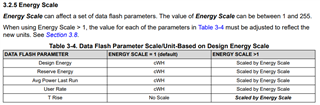

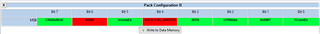

I am trying to perform a Learning Cycle using the BQ34Z100-R2 on the TI EVM board connected to a 4S LFP battery. Spec is 12V 160Ah. Current and energy have both been scaled by 5 such that 160A reads 32000mA. Programmed ChemID is 400, which is not the exact cell I am using but according to GPCCHEM is the closest match with 7.59% max DOD error.

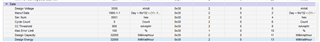

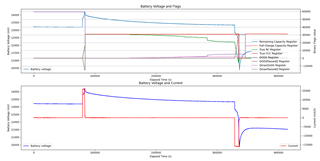

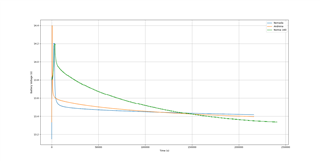

When attempting the learning cycle, it detects charge termination just fine, updates LearnedStatus to 0x05 almost immediately upon raising the FC flag (I'm assuming this is due to the LIFE mode set by the chemistry programming), but does not update to LearnedStatus 0x06 after a subsequent discharge, indicating that it is not able to learn Ra.

I checked the logs and RUP_DIS was not raised during discharge, the discharge rate was set to C/5, but I did notice that the value of GridNumber only spanned 1-13 over the discharge, where the Ra table in flash contains grid points 0-14.

A few questions arise:

- Is it correct that the gauge does not enter REST mode after charge termination, even though the battery was left to relax overnight (with power supply and load disconnected with a relay) before starting discharge?

- Why does the resistance table not get fully updated before terminate voltage? Is there a flash or config setting that I am missing here?

- Why does the gauge not enter REST mode when relaxing for more than 5 hours after discharge?

- Are there other indicators as to why the Learning Cycle is not updating to 0x06 that I should fix? Am I doing something wrong in the learning cycle procedure? Is the programmed chemistry too far off of the cell in use such that the Impedance Tracking algorithm gets confused?

Logs of the failed learning cycle and a .gg export of the data flash values taken after the learning cycle are attached.

dataflash_after_failed_LearningCycle.gg.csv2nd_attempt_LearningCycle.log