Other Parts Discussed in Thread: EV2400, BQ34Z100EVM, BQ34Z100-G1

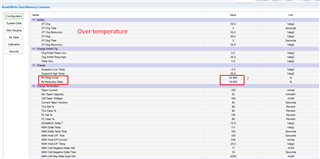

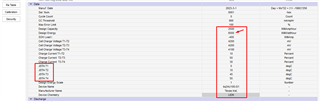

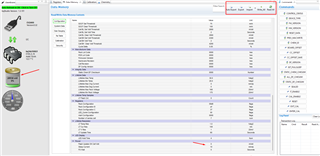

I am getting this error when i select desire chip in bqstudio. What i should do for it?

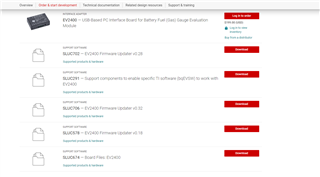

Also, i have EV2400 with firmware version 0.18. What version should i install it from website because there are 3 versions available? what's the difference?

Last, i checked some videos about golden image programming of BQZ. Is there any document that i can follow to setup for the battery?

The three video's available for it but they do voltage/current calibration. I just want to evaluate simple mode but not advance for the sake of learning and testing.