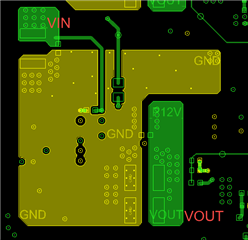

Other Parts Discussed in Thread: TPS552882, TPS55288

hello,

TPS552882-Q1 Why is it always buck first and then boost in buck-Boost mode?

In theory, when VIN<VOUT, should be boost first, then buck; When VIN>VOUT, it should be buck first and then boost.

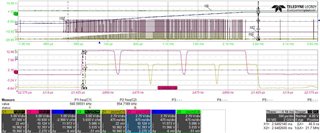

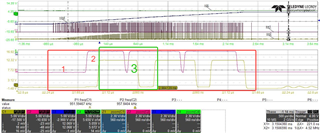

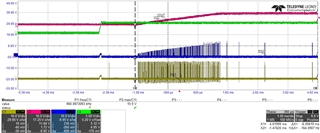

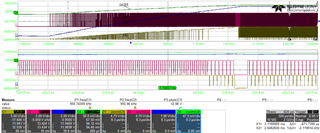

Waveform as follows:

The waveform at 9.8V

The waveform at 13V