Other Parts Discussed in Thread: BQSTUDIO

Hi

I have a query need your help.

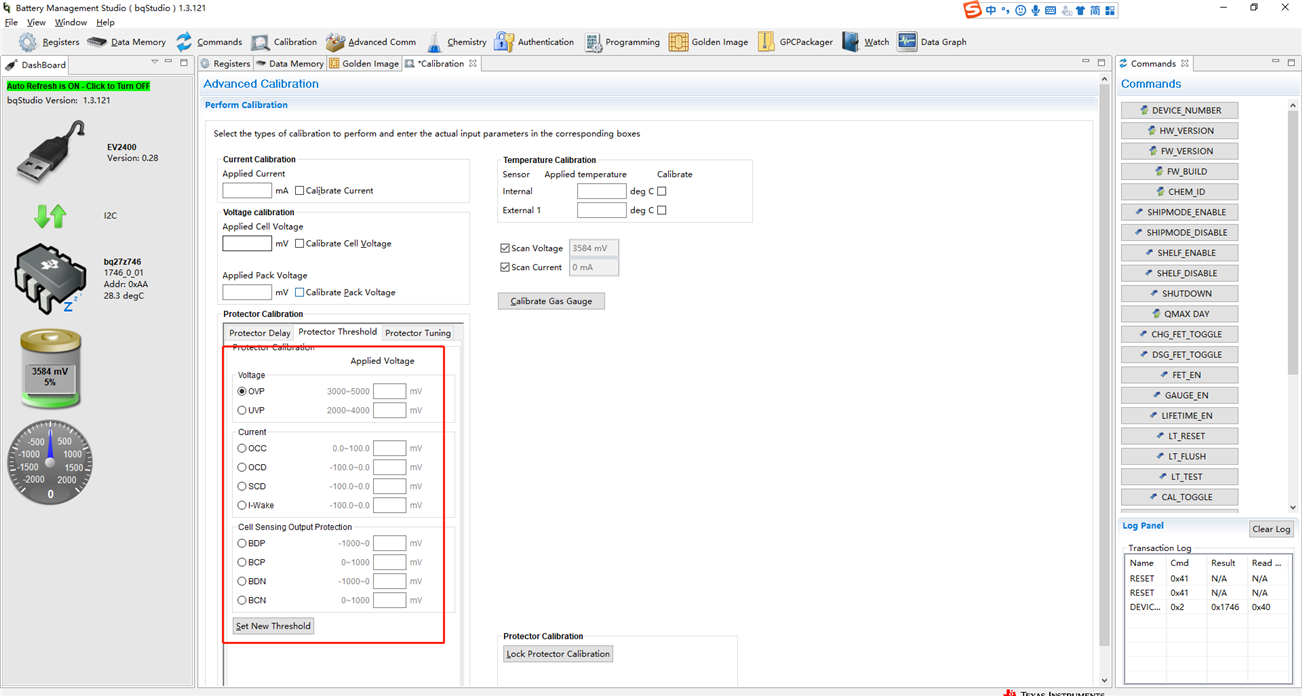

The calibration values marked by the red line are not stored in the Data memory. In actual production, it is impossible for every product to do this calibration.

How can I save the protector calibration of this part in the golden image.

Waiting for your reply.

Thanks

Star