Hi Sir,

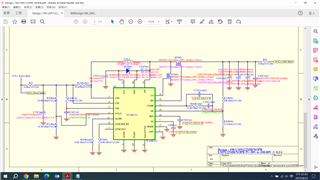

We had already referred to the reference design(WBDesign198_LM5122MH_reference design, designed from TI side) to finish our schematic(Design_198 LM5122MH_NOPB) but the LM5122 boosting function failed fully.

The target specification is listed below.

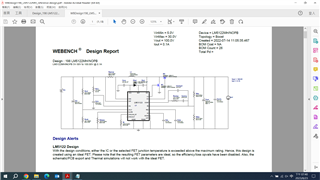

Design : 198 LM5122MH/NOPB

LM5122MH/NOPB 5V-30V to 100.00V @ 0.1A

VinMin = 5.0V

VinMax = 30.0V

Vout = 100.0V

Iout = 0.1A

Device = LM5122MH/NOPB

Topology = Boost

Created = 2022-07-14 11:05:35.467

BOM Cost = NA

BOM Count = 26

Total Pd =

TI's on-line FAE had ever pointed out the boosting function failure should be caused by the Q2 mosfet which is with incorrect pin design in my schematic, the drain pin and source pin shall be swapped to have a correct design.

I did follow this comment and replace with a new mosfet(with the totally same part) and get the two pins swapped but the boosting failure is still the same. That is the Vout voltage(DC 10V) is almost same as Vin(DC 10V) under no load condition so far.

Can you please kindly advise me how to fix this boosting failure issue?

Much appreciated in advance!

Best Regards,

Bob Chen 2023/08/23