Other Parts Discussed in Thread: GPCRB, BQSTUDIO, EV2400

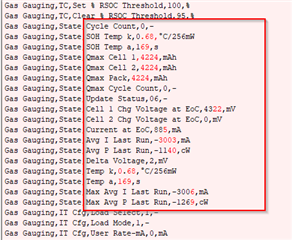

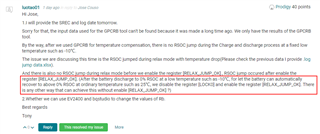

After the battery discharge to 0% RSOC at a low temperature such as -10℃, for let the battery can automatically recover to above 0% RSOC at ordinary temperature such as 25℃, we closed the register [LOCK0] and opened the register [RELAX_JUMP_OK].

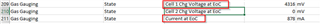

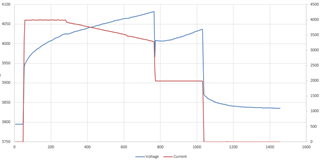

Then we conducted another charge test:

Place the machine with battery in the incubator and plug in the adapter, the setting of the incubator is: cyclic variation between -10℃ and 50℃ change by 1℃ per minute, maintained at -10℃ and 50℃ for one hour each, until the charging is completed. the machine will not charge at temperature below -10℃ and above 45℃.

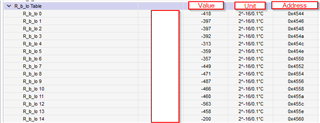

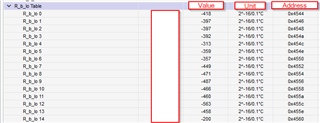

The temperature at the beginning of the test was 25℃, and then the temperature decreased during the charging process, when the temperature drop to 0℃, the battery stopped charge and discharge and switch to adapter for battery power supply. When the temperature continues to drop to -1℃, the RSOC jumped from 34% to 4%.

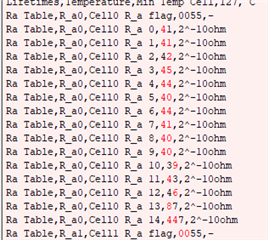

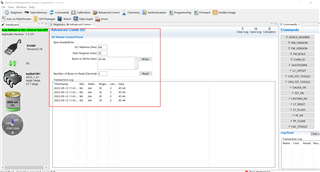

This jump can be improved?The gg file as the attachment.5305.gg.csv