Hi team,

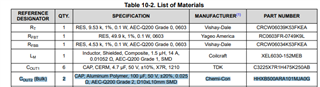

Q1. Lookign at the table 10-2,alminium electric cap(100uF, ESR25mOhm) x 2pcs are used. Instead of alminium electric cap, can MLCC more than 50uF be used?

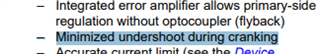

Q2. Could you tell the details about "minimized undershooot during cranking"?

Q3. Are there any data about the line transient?

Regards,

Noriyuki Takahashi