Other Parts Discussed in Thread: TPS552882, TPS55288, , TPS55288-Q1

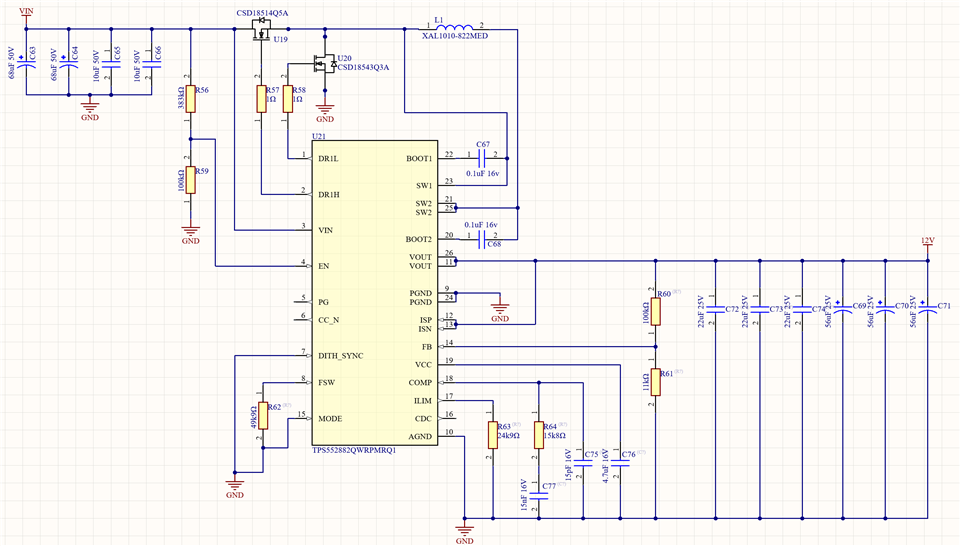

Hi, I have a schematic based on a webench solution which I have modified slightly and I just want to check if everything looks ok. It is for 6-36V input with a 12v 6A output.

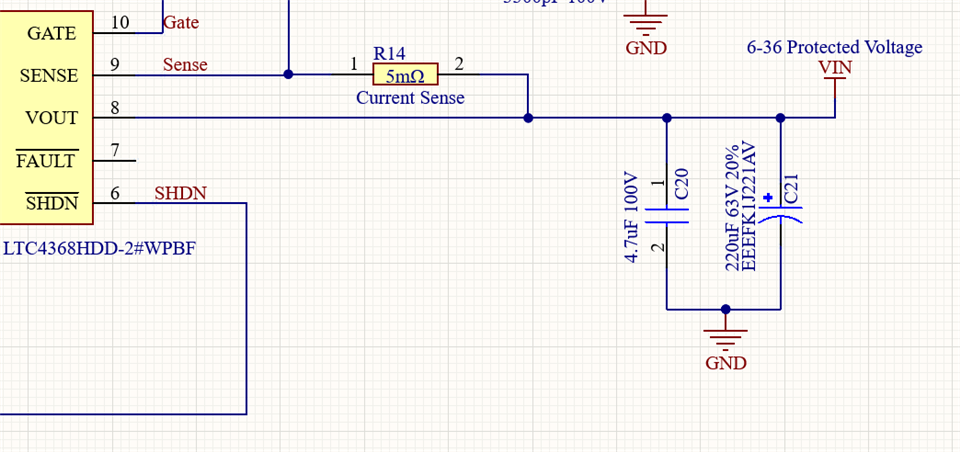

1 question I have is about the input and output capacitors. Are the large aluminium capacitors necessary? I saw on the datasheet that they don't put them in the example application but they are added on webench. I have this as this power feed which supplies the VIN input to this circuit:

It already has a large 220uF capacitor. Can I change the aluminum ones on my buck-boost?

Thanks all!

3D

3D Tranp

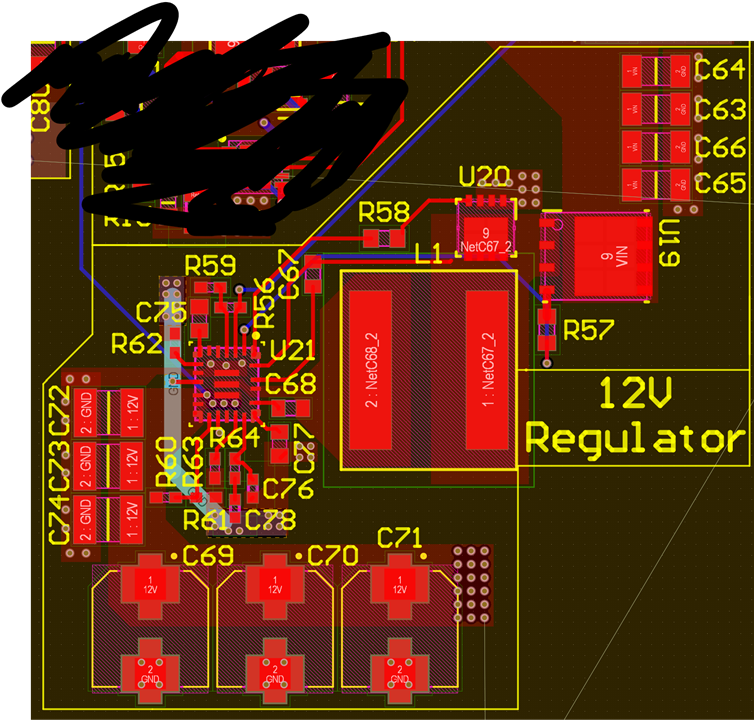

Tranp Top Layer

Top Layer L2 - GND

L2 - GND L3 - Contains AGND

L3 - Contains AGND Bottom layer

Bottom layer Schematic

Schematic