Other Parts Discussed in Thread: TIDA-010047, TIDA-01623, BQ25731, BQ25730, BQ25756, TPS25751

Hi,

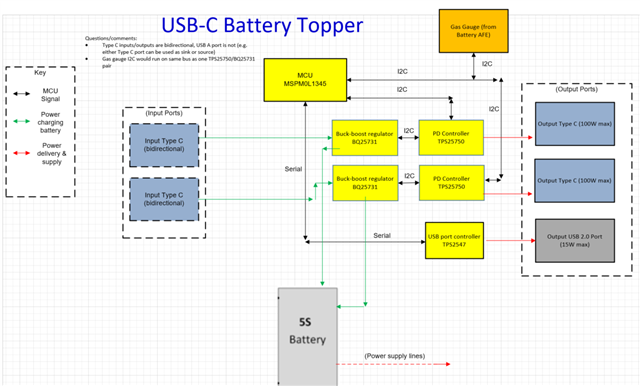

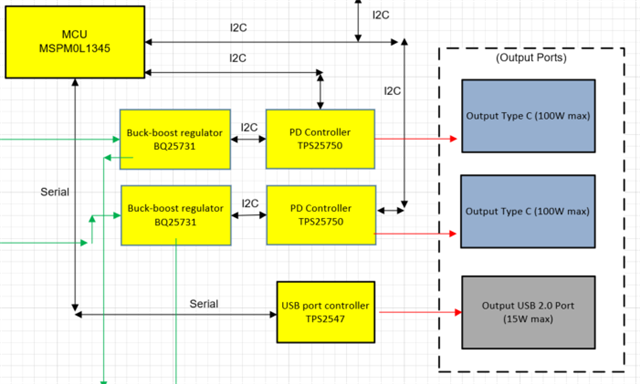

I am trying to find some guidance on power negotiation. The application is a battery topper that would be placed on an existing 5s (18V) battery and ideally, I have 2 USB-C ports that output up to 100W and 1 USB A port that outputs up to 15W. The customer would also like to be able to charge the battery through either USB-C port. I have looked into the TPS25750 and am not sure if I could use two of these to accomplish what I am trying to do with the USB-C ports. I want to know if I am charging the battery with 1 USB-C port while charging a device through the other USB-C port, how I would negotiate the power. Or if I am charging devices through both USB-C ports, can I negotiate independent voltage contracts? I want to charge the battery and the devices as fast/much as possible given the USB-C compliance.

Is there a reference design you can point me to? I have found TIDA-01623 and TIDA-010047 which are 100W applications but not quite what I am looking for.

Thank you,

Randy