Other Parts Discussed in Thread: BQ27426, , BQ27Z561, BQ27Z561-R2, BQSTUDIO

Hi,

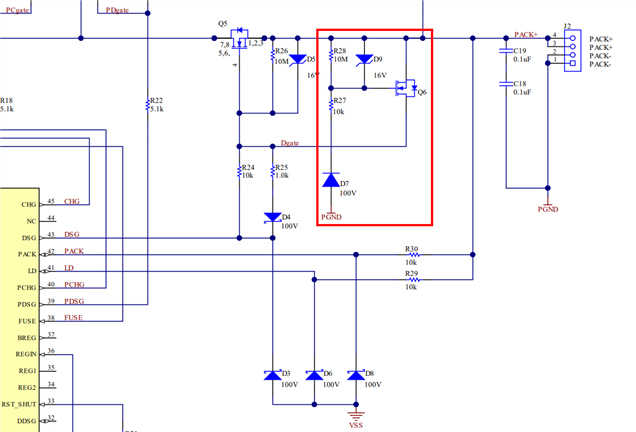

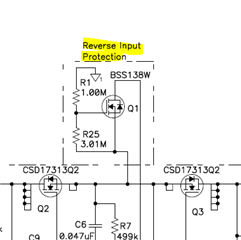

We are using BQ24171 charger and BQ27426 battery gauge in our board. It will be connected to a 2P 3.7V battery.

I have attached our schematic for your reference. Please review it and give us your feedback.