Hello,

When do you use copper-defined vs. solder-mask defined landing patterns? And what are the tradeoffs?

Thank you!

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hello,

When do you use copper-defined vs. solder-mask defined landing patterns? And what are the tradeoffs?

Thank you!

Hello Owens,

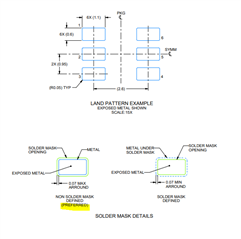

Looking at the recommended footprint, both are possible. The drawing states NSMD pads as preferred - I think this is true in general.

This is due to solder joint reliability and better control of the artwork. Here is an app note that discusses this in more detail. This is for a different package but the tradeoffs are the same.

See page 8:

https://www.ti.com/lit/an/snoa021c/snoa021c.pdf#page=8

The LMR51610 package has leads so this is probably less of a concern from BLR standpoint.

If multiple pins connect to the same copper pour/copper island, SMD pads would make more practical sense.

Regards,

Denislav