Other Parts Discussed in Thread: EV2400

Hi,

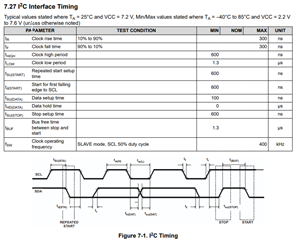

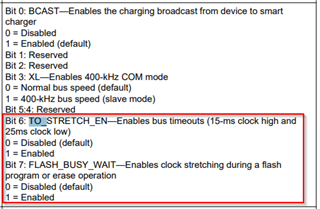

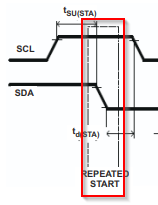

We are using the BQ28Z610 fuel gauge in a battery design, used in one of our products. We are currently having issues communicating with the fuel gauge over I2C, in high-speed mode (400kHz). We are able to communicate OK at 100kHz using our product. We can communicate OK at 100KHz and 400kHz using the EV2400 eval module. We have used the EV2400 to set the XL bit in I2C Configuration but doing this seems to cause the I2C bus to hang on our product setup, when running at 400kHz.

Can you please provide guidance? I have read about several people having issues with the 400kHz mode on this IC

Thanks,

Robert White