Hi Folks

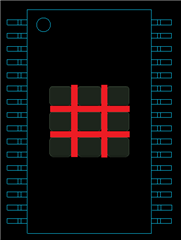

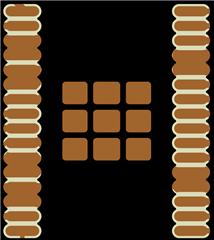

I have a question, what is better a hatching heat dissipation PAD or "square" complete PAD?

Texas Instruments always recommend a complete PAD for heat dissipation, but now we have these footprints with hatched PADs in our libraries,

but I don't know this will be affect the heat transfer to the PCB and increase the thermal resistance.

Thanks in advance.

Hector A.