Hi,

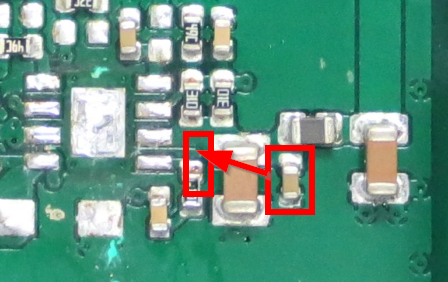

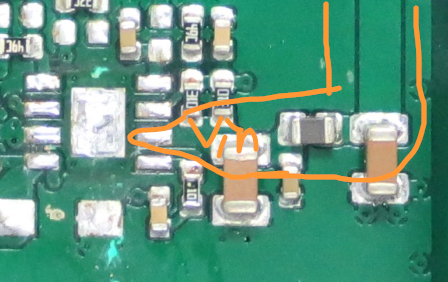

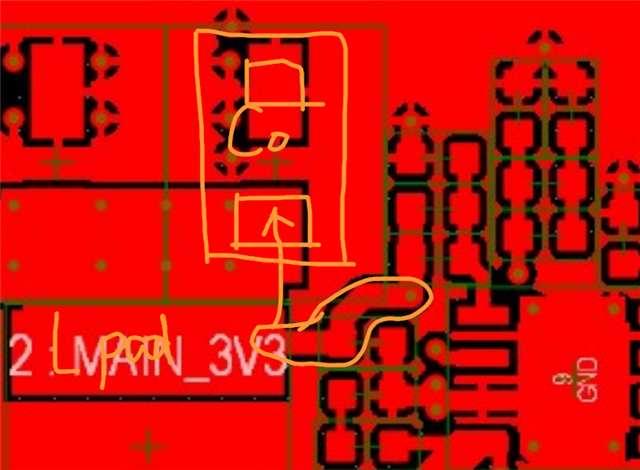

We’ve had 4 instances now with our product in a particular geographical location whereby the 3.3V supply circuit has failed. On review of the failures, the catch diode has failed short and, in 3 units, the TPS54331 was also faulty (had to be replaced).

Units have been running for a few years and then fail. Units are operated 24/7 but may be power-cycled during maintenance of other equipment at the location. We are trying to determine if there is any link between the maintenance activity and the failures but this is not yet forthcoming.

The same product is used world-wide and we’ve had no reports of failures from any other location. We would like to determine the cause of this failure or if there are any tests we could do to replicate the failure.

The attached document shows schematics and PCB layout. I've also attached some Webench designs that were done at the time of product development and a spreadsheet of calculations.

Thanks,

Kieran

Failure of TPS54331 circuit.pdf24V-to-5V at 0.5A using TPS54331DDAR (TI Webench design #73 - 28-Mar-19).pdf24V-to-3V3 at 0.5A using TPS54331DDAR (TI Webench design #72 - 28-Mar-19).pdf24V-to-3V3 at 1.5A using TPS54331DDAR (TI Webench design #73).pdfDesign Calcs for 24V-to-3.3V using TPS54331.xlsx