Other Parts Discussed in Thread: LM3410, TPS61288

Hi,

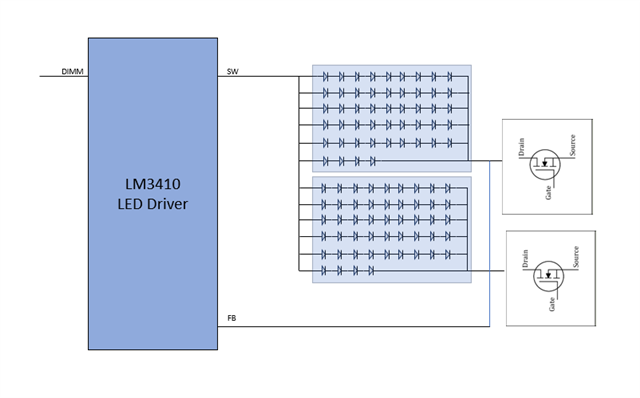

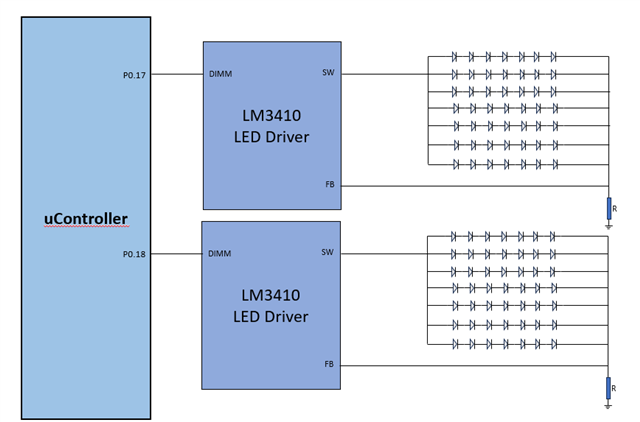

I am looking for a LED driver for my new product design which should be able to drive 98 laser diodes whose Vf= 2.4V and If= 70mA.

Input voltage to LED driver 3.3V.

LM3410-Q1 has around 85% efficiency for this input voltage.

Does TI have any better part than LM3410-Q1 or this one is good enough for the above application?

Thanks,

Gaurav