Other Parts Discussed in Thread: TPS54360

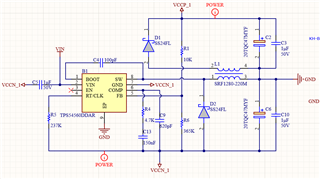

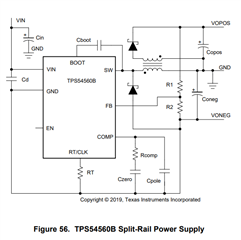

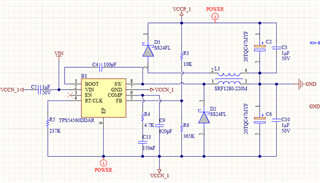

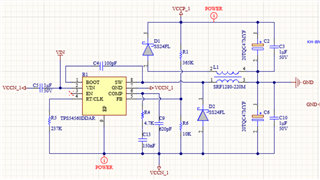

I've designed a circuit referring to the document SLVA369A using TPS54560, it has 24V input and ±15V output. but when I turn the input 24V on, nothing happened. I've compared my design to the document, but I didn't found any difference. The value of the resistor and capacitor is calculated using the SWIFTPOSNEG-CALC-v4.xlsx tool. I'm sort of a newbie to power design, and I really can't find out where the mistake is. Can anyone help me to correct my design? That would help a lot.