Hi all

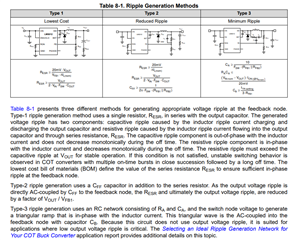

I'm designing step-down converter with LM5012. Convert 48V input to 12V output

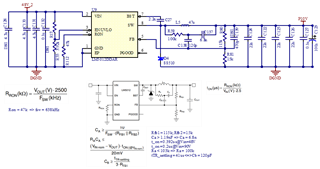

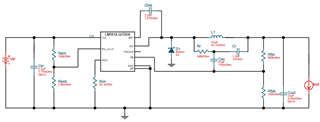

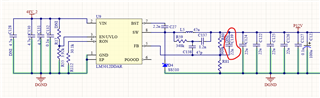

I using WEBENCH to generate design as below

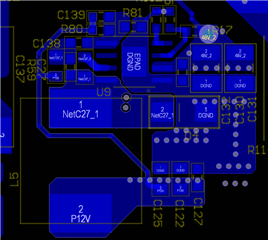

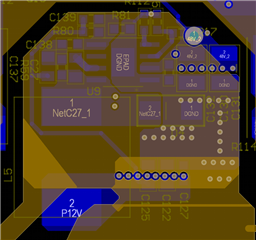

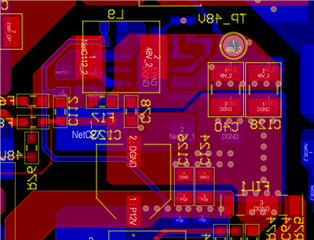

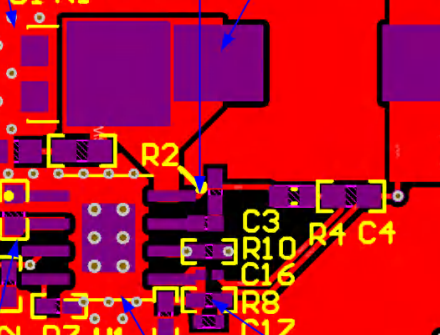

and have PCB with schematics as below (note that C139 wasn't fitted)

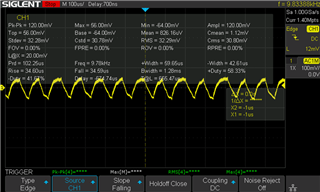

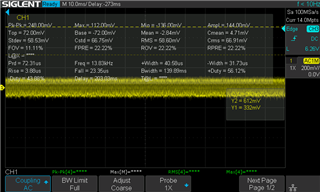

But it have big ripple, about 260mV pk-pk, ripple on scope as below

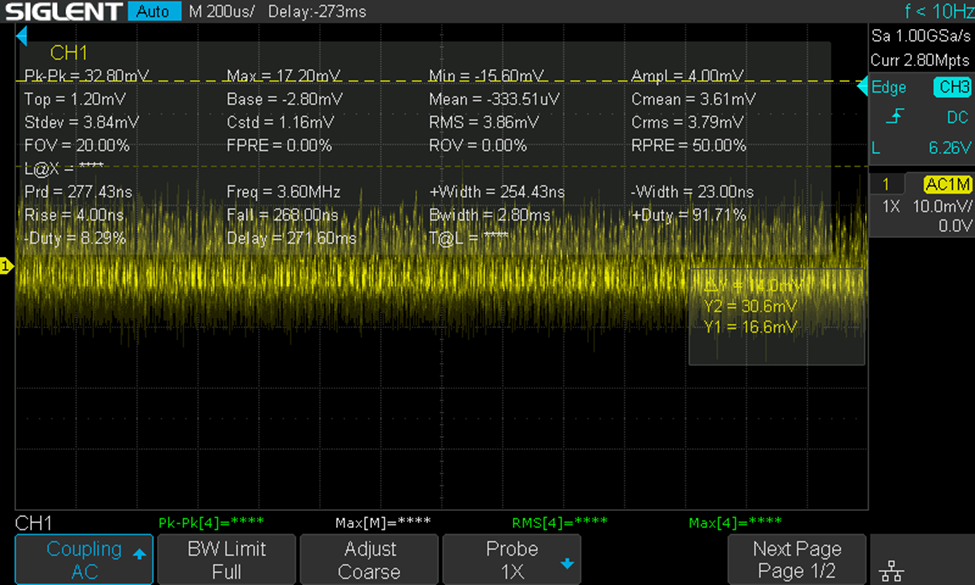

After that, I solder C139 with 22nF, (some others buck converter recommend fit this cap, but LM5012 not refer to this cap in the datasheet) and the ripple reduce significantly, to 32mV pk-pk, as below

But this circuit ran into problem after few week, that is, output voltage not reach to 12V, about 4V- 5V. however, when I take out C139, voltage recovery to 12V and every thing work ok (except the big ripple as mention above)

So, any one know the root cause of this issue? how I can reduce the ripple when not have C139 (because this cap isn't on the example design in datasheet)