Good morning,

We are designing a pcb with 2 TPS54313PWPR units.

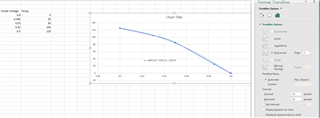

And we detected temperature issues, by using Rth provided by datasheet.

Please, could you share the R-2R thermal model, or Delphi thermal model to simulate it in Flowtherm software?

At least, the Rthj to thermal pad.

Thanks you in advance,

Regards

Daniel