Other Parts Discussed in Thread: LM5156

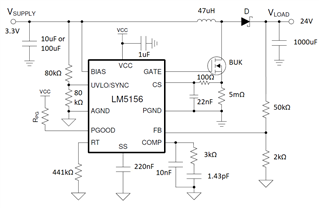

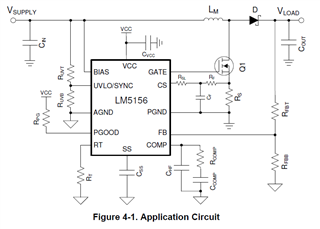

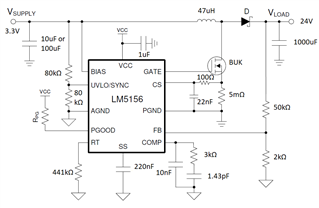

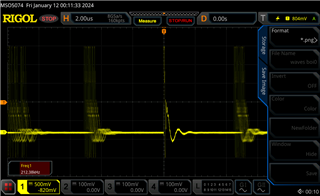

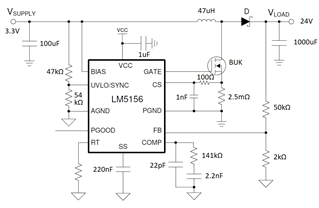

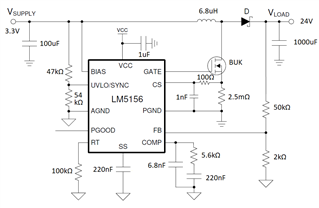

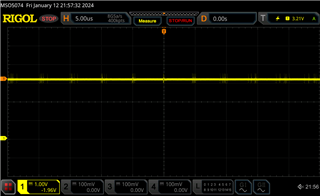

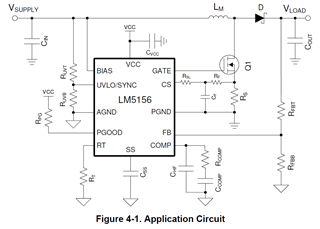

We have been designing a boost circuit to take a 3.3V @30A source up to 24V @ 2A. I went through the calculations within the "How to Design a Boost Converter Using the LM5156" instructions, but ran into a couple hiccups throughout the actual implementation. The design is shown below:

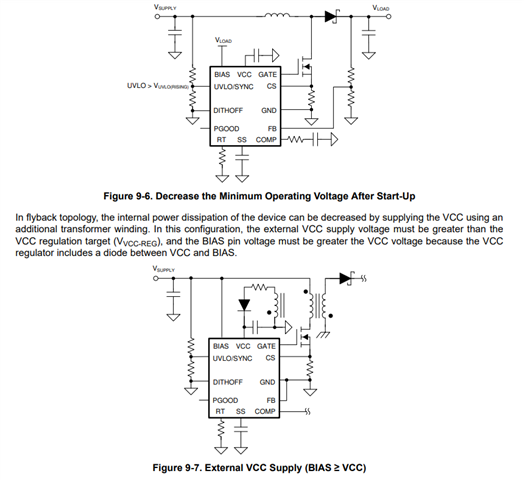

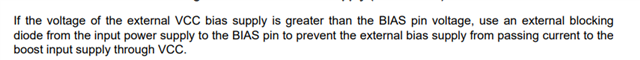

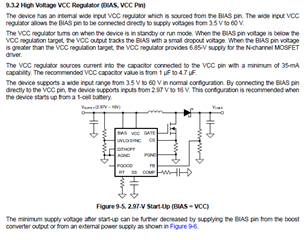

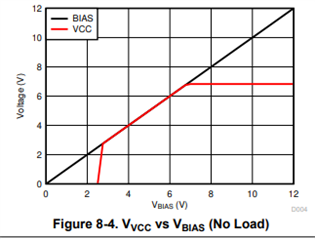

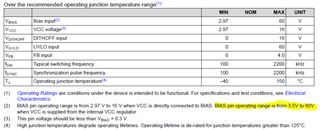

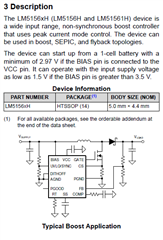

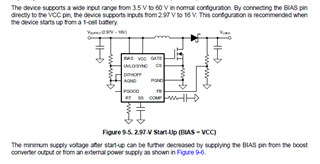

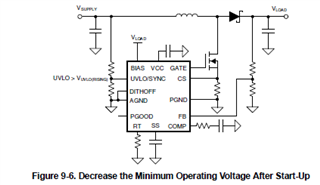

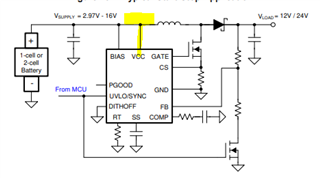

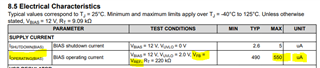

The design has Vcc decoupled from the Bias pin, but in the datasheet there is a configuration where they are connected. There is also these notes about Vcc and the Bias pin:

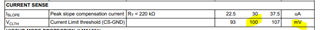

Since our input is 3.3V, The notes show I should connect the two, but this isn't shown on the boost calculation guide. Below is our calculated values for our design. Please let me know if something doesn't look correct, I am struggling to find where this is going wrong.