Other Parts Discussed in Thread: UCC27324

Hello my name is Stephen from Zed Audio. I have designed a 5Kw PFC using the UCC28070 and have optimized my drive circuit using your on line Power Designer. I am not able to achieve a decent efficiency figure. I do note that in your Power Designer there are 2 errors. The capacitors on the CSA and CSB are shown as 220nF.

I designed my schematics from your UCC28070 PDF files as well as a spreadsheet I received from Ti. I am running at 100KHz and I can exchange the UCC28070 drive board configured for 50KHz and there is no difference in efficiency

The only difference between my design and your Power Designer is that I am using 250uH inductors on Micrometals T250-18 cores. Your Power Designer does not seem to specify what turns ratio the two current transformers should have. I am using 1:200 CS4200V-01L types.

Loading the 380v output at 534w, efficiency with a 208v AC input is 89% and the Power factor is 0.90 Regulation is perfect at 100%.

Loading the 380v output at 850w, efficiency with a 208v AC input is 88.5% and the Power factor is 0.963 Regulation is perfect at 100%.

Loading the 380v output at 1450w efficiency with a 208v AC input is 88.9% and the Power factor is 0.981 Regulation is perfect at 100%.

I am using a 4 layer PCB with power and ground planes. My current loops are kept small and tight.

IGBTs are HGTG30N60A4D and I am using 4 pcs each with 24R9 gate resistors (10R gate resistors did not change efficiency BUT the 24R9s lowered EMI and interference with my class A/B amplifiers which hang off a half bridge supply working of course from the PFC.Each pair of IGBTs are driven from a UCC27324 with all the correct supply bypassing.

PFC diodes are SiC STPSC40065C

I have snubbers across each pair of IGBTs at 500pF series 10R which reduced EMI a lot.

I have 2mfd after my mains rectifier and 3300mfd post PFC.

I designed a slow startup circuit added to the UCC28070 drive board which ramps up the PFC voltage over about 30 seconds which allows me to have zero in rush current.

All parts are SMD of course except for inductors, IGBTs, PFC diodes and current transformers.

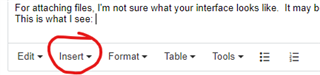

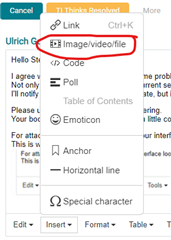

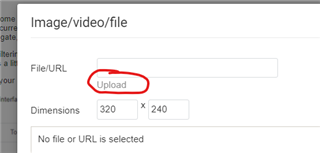

This is the first time I am using this forum and if you require me to post my schematics, please can you advise how I do that.

I do not know how you notify me when this post is replied to but here is my email address to contact me. smm@zedaudiocorp.com