Other Parts Discussed in Thread: BQ25756

Hi TI,

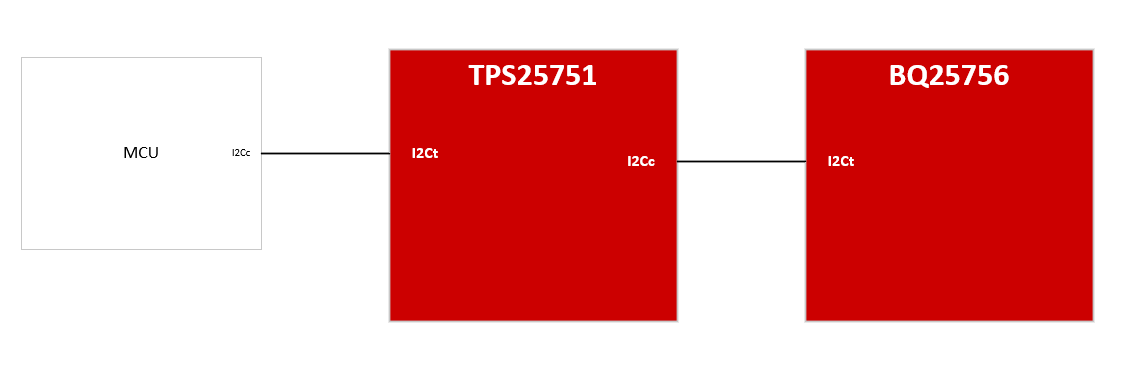

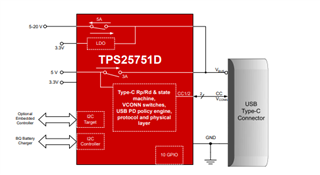

We want to develop a portable charger with TPS25751 and BQ25656, controlled over I2C from microcontroller. Due to two Type-C ports, we designed to use two pairs of TPS25751 and BQ25656:

The questions are as following, could you kindly give some suggestions? Thanks.

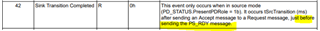

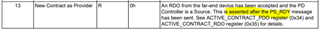

1.Since TPS and BQ are both controlled by MCU via I2C, how do they coordinate under this circumstance? i.e, what register should we read from TPS to configure BQ, and vice versa?

2.Without MCU control, what would happend if the following situations occur?

(1)Both Type-C ports are connected to connected to the chargers with the same specification respectively. For example, Port-1 connects with 20V, 3A charger, Port-2 connects with 20V, 3A charger. Would the charger current to Battery be the sum of BQ-1's and BQ-2's output IBAT?

(2)Type-C ports are connected to the chargers with the different specifications respectively. For example, Port-1 connects with 20V, 3A charger, Port-2 connects with 5V, 1A charger.

(3)Port-1 connects with charger, Port-2 connects with consumer such as mobile phone.