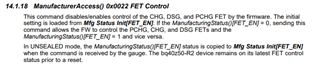

Hello, we are using the BQ40Z50-R2 fuel gauge in our design. The implementation follows the typical application shown in the datasheet. When powering the board for the first time, after waking up the fuel gauge it seems that all FETs are closed. If I understand correctly this is normal behavior because the wake up process includes a Reset which shuts down the FETs. Is that correct?

Does this mean that we need to instruct the fuel gauge to toggle the FETs every time we power the board? If yes, do we need to toggle all three FETs or toggling one would get things started and the others will be controlled by the fuel gauge?

Thank you,

Noam