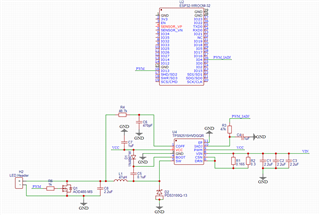

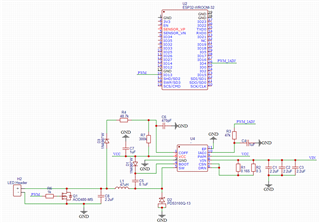

I am looking for a buck converter as a variable constant current source for the operation of approx. 3-6 LEDs.

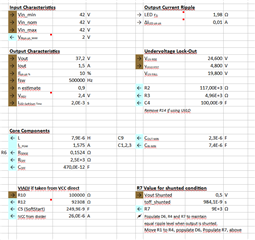

Requirements:

- Current (0.35A ~ 1A) controllable via microcontroller (perhaps via digital potentiometer on the pin for current control?)

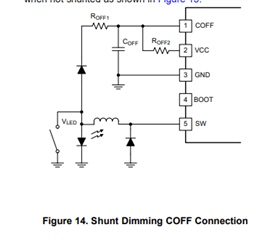

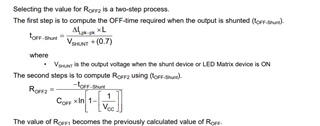

- PWM in 256kHz controllable via microcontroller with possibility to change the duty cycle 128000 times per second

- or possibility to put a MOSFET at the output for PWM control via microcontroller

- Lowest possible power dissipation

- Operation on 18V or 24V direct current