Other Parts Discussed in Thread: TPS922055

Hi Team,

Use TPS922055 driver LED lamp, 36V power, output voltage 20-25V, current 3.5A.

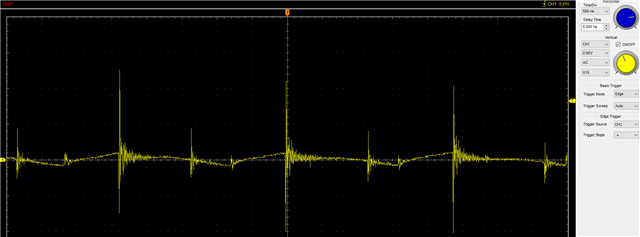

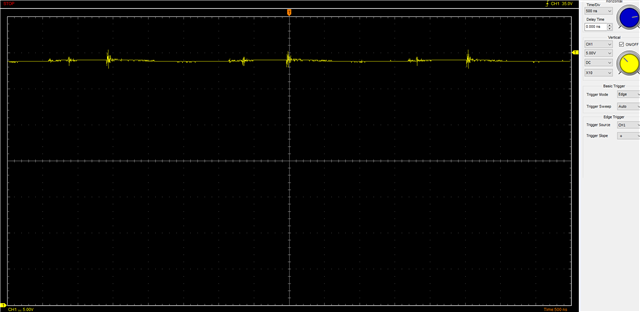

Use the oscilloscope to check the chip 14 pin SW, when the PWM is less than 10%, the output waveform interference is large (PWM is more than 20% waveform is better).

Double-sided circuit board design.

There are two sets of independent output circuits on a circuit board.

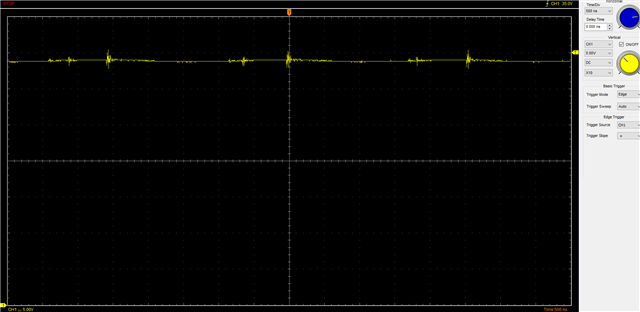

36V power waveform also has large interference, how to improve?

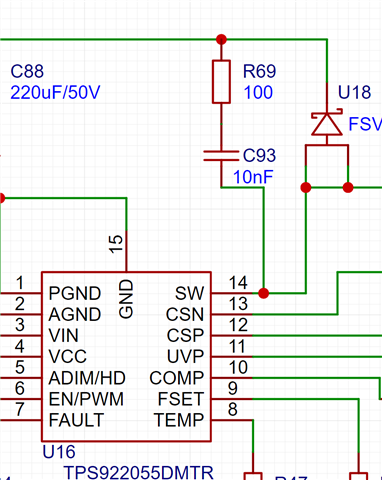

The schematic diagram is as follows:

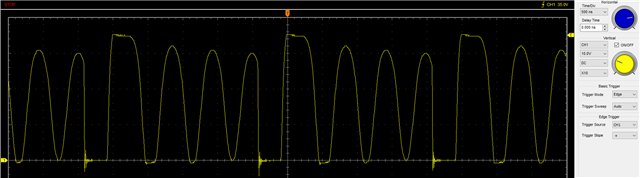

SW waveform diagram is as follows: (@10%PWM)

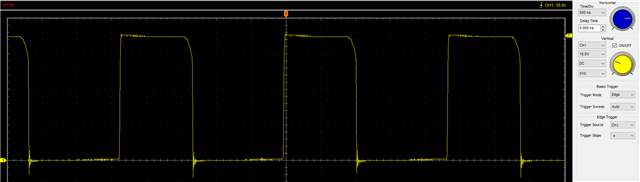

SW waveform diagram is as follows: (@20%PWM)

36V power waveform diagram is as follows:

Best Regards,

Kevin