Dear TI team,

I am observing pulse narrowing in the output gate signal of UCC28C43DR IC.

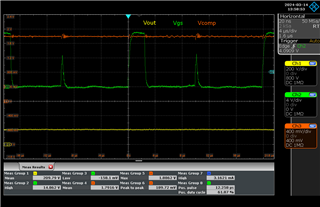

For which I have probed following signals

1. Gate pulse and Sense pin voltage

2. Gate pulse and COMP pin voltage

I found no issues with COMP pin voltage and sense pin voltage which is used to terminate the output pulse.

Please let me know what can be possible cause of this narrow pulse.