Other Parts Discussed in Thread: BQ25601D, BQ25601, BQSTUDIO

Hello TI Team,

We have used BQ25601D Charger and BQ27Z561 fuel gauge in our custom board.

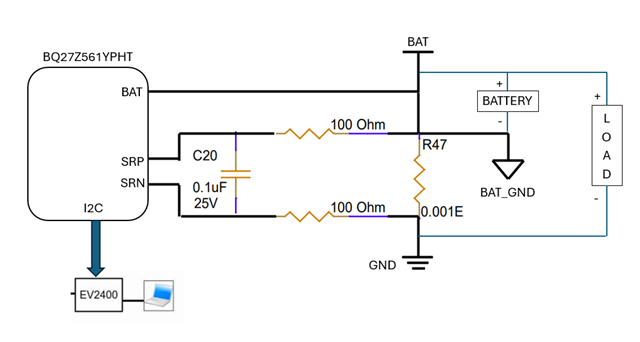

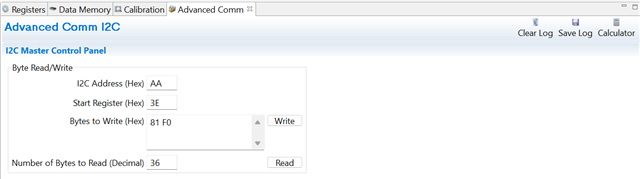

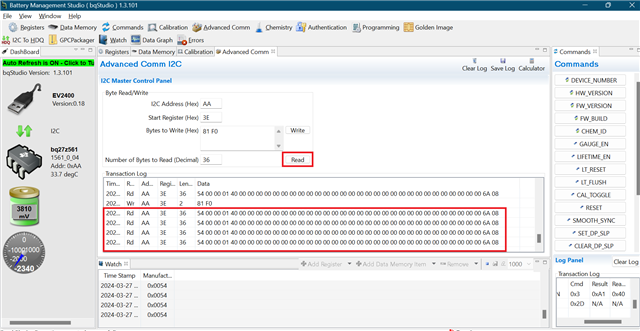

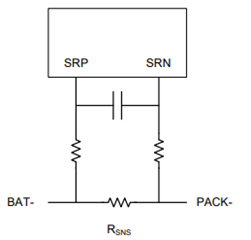

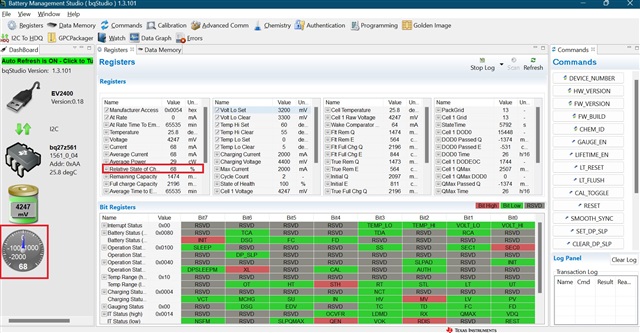

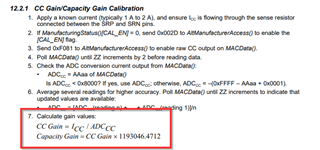

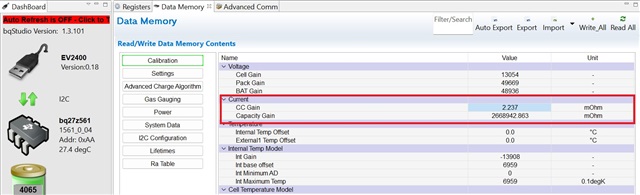

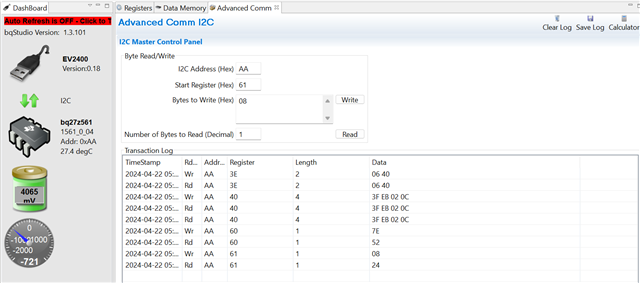

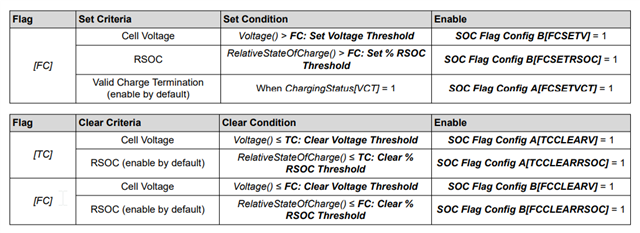

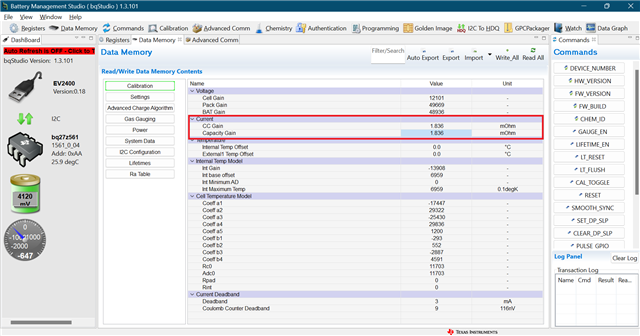

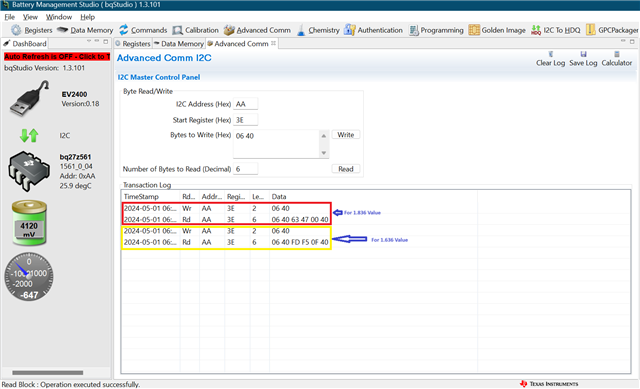

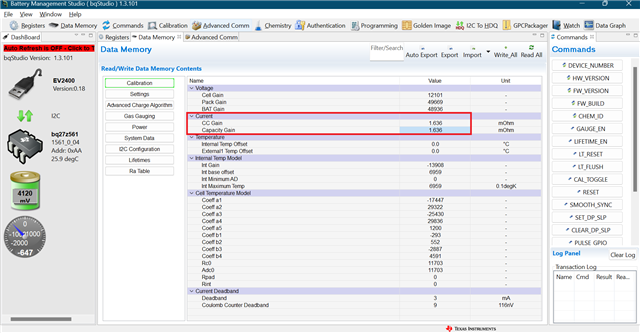

We did POC which is having 12Layer HDI stack up with 1mOhm current sense resistor at fuel gauge side (across SRP and SRN pin). And we are getting proper behaviour/results in terms of Charging current (2A we are setting), Charge Termination, Capacity reading.

Now, Actual board is having 4Layer through hole stack up with same 1mOhm current sense resistor. There are no change in shcematic and BOM between POC and actual board.

And with actual board, we are facing issues mentioned below.

- Charging current read by fuel gauge is 3A even though we are setting the 2A.

- We are getting continuous charger interrupt and getting below errors.

- After getting many of the below errors, the board will go into not charging state.

-------------------------------------------------------------------------------

[ 709.600214][ C0] i2c_geni 984000.i2c: Bus proto err, noisy/unepxected start/stop

[ 709.608782][ T339] i2c_geni 984000.i2c: i2c error :-71

[ 709.614298][ T339] bq25601-charger 0-006b: Can't read F reg: -71

[ 709.620729][ T339] EIC :: [1553|bq25601_irq_handler_thread]

[ 709.638889][ T3435] i2c_geni 984000.i2c: IO lines in bad state, Power the slave

[ 709.646573][ T3435] [bq27z561] __fg_read_word: Battery not detected, i2c read word fail: can't read from reg 0x2C

[ 709.649400][ T339] i2c_geni 984000.i2c: IO lines in bad state, Power the slave

[ 709.664755][ T339] bq25601-charger 0-006b: Can't read SS reg: -6

[ 709.666022][ T3435] [bq27z561] fg_read_rsoc: Battery not detected, could not read RSOC, ret = -6

[ 709.671214][ T339] EIC :: [1553|bq25601_irq_handler_thread]

[ 709.680255][ T3435] power_supply bms: driver failed to report `capacity' property: -6

[ 709.681206][ T380] i2c_geni 984000.i2c: IO lines in bad state, Power the slave

[ 709.701921][ T380] [bq27z561] __fg_read_word: Battery not detected, i2c read word fail: can't read from reg 0x0A

[ 709.701926][ T380] power_supply bms: driver failed to report `status' property: -6

[ 709.702245][ T339] i2c_geni 984000.i2c: IO lines in bad state, Power the slave

[ 709.702256][ T339] bq25601-charger 0-006b: Can't read SS reg: -6

[ 709.735501][ T380] i2c_geni 984000.i2c: IO lines in bad state, Power the slave

-----------------------------------------------------------------------------------

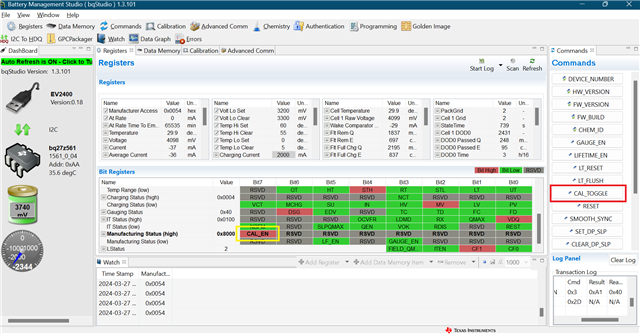

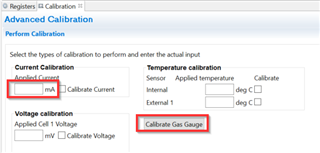

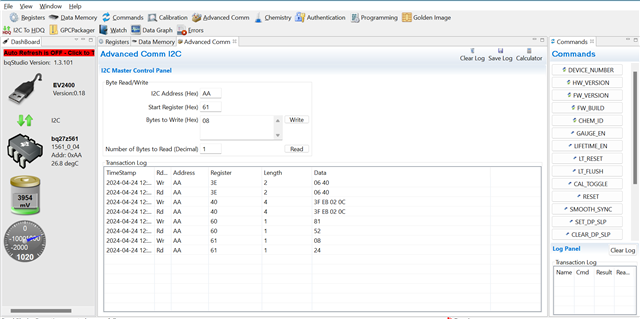

So, here we have not performed the learning cycle with actual board. We are using the same golden image which is generated with POC board.

Here, is it required to perform the learning cycle with Actual board?

Kindly provide your inputs.

Thanks,

Shivani patel