Hi,

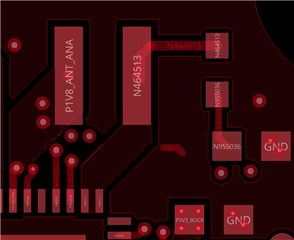

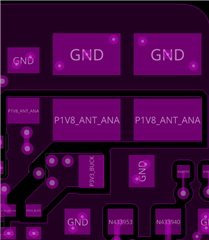

We're using the TPS65940400RWERQ1 and are debugging an issue where:

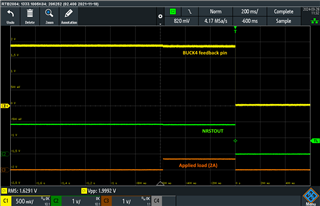

- PMIC shuts down (nRSTOUT is deasserted) and is no longer accessible over i2c (using EVM and PMIC-GUI 3.0.0) after applying a 2A load on BUCK4.

- PMIC seems stuck in this state and requires a power cycle to start back up.

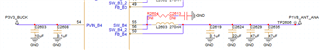

This seems isolated to the BUCK4, loading BUCK3 in the same manner does not cause shutdown. The BUCK4 should be good for 4.5A and we fail already at 2A.

The steps to trigger the behavior is as follows:

- Power up board - OK

- Check PMIC status over I2C - OK

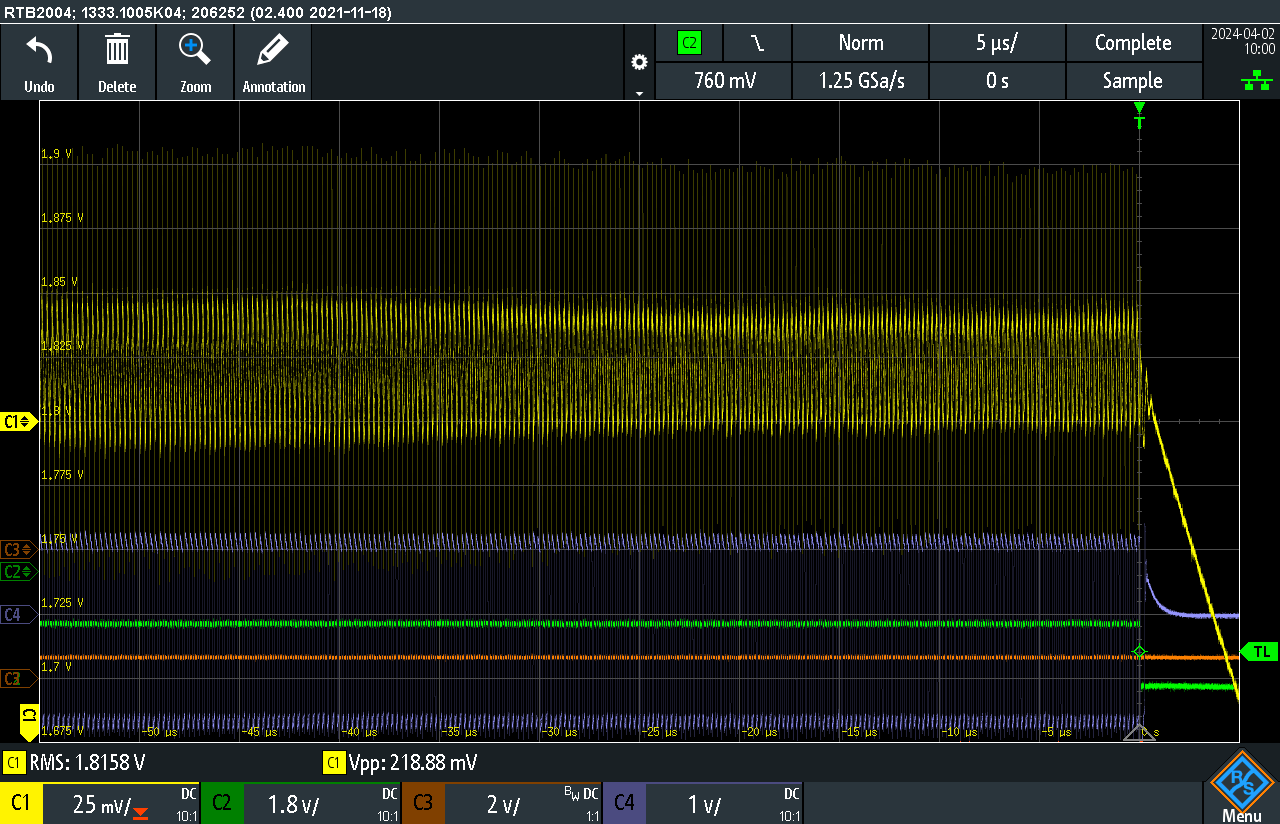

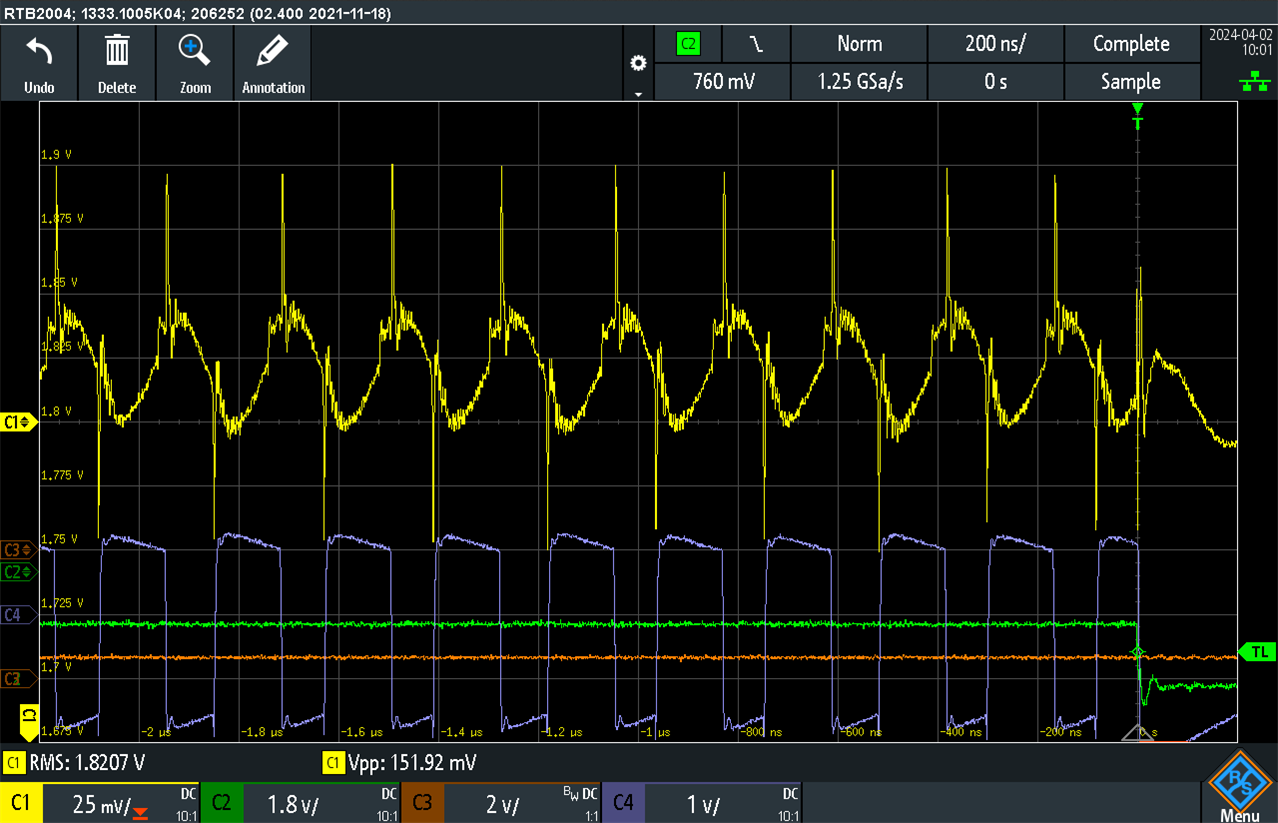

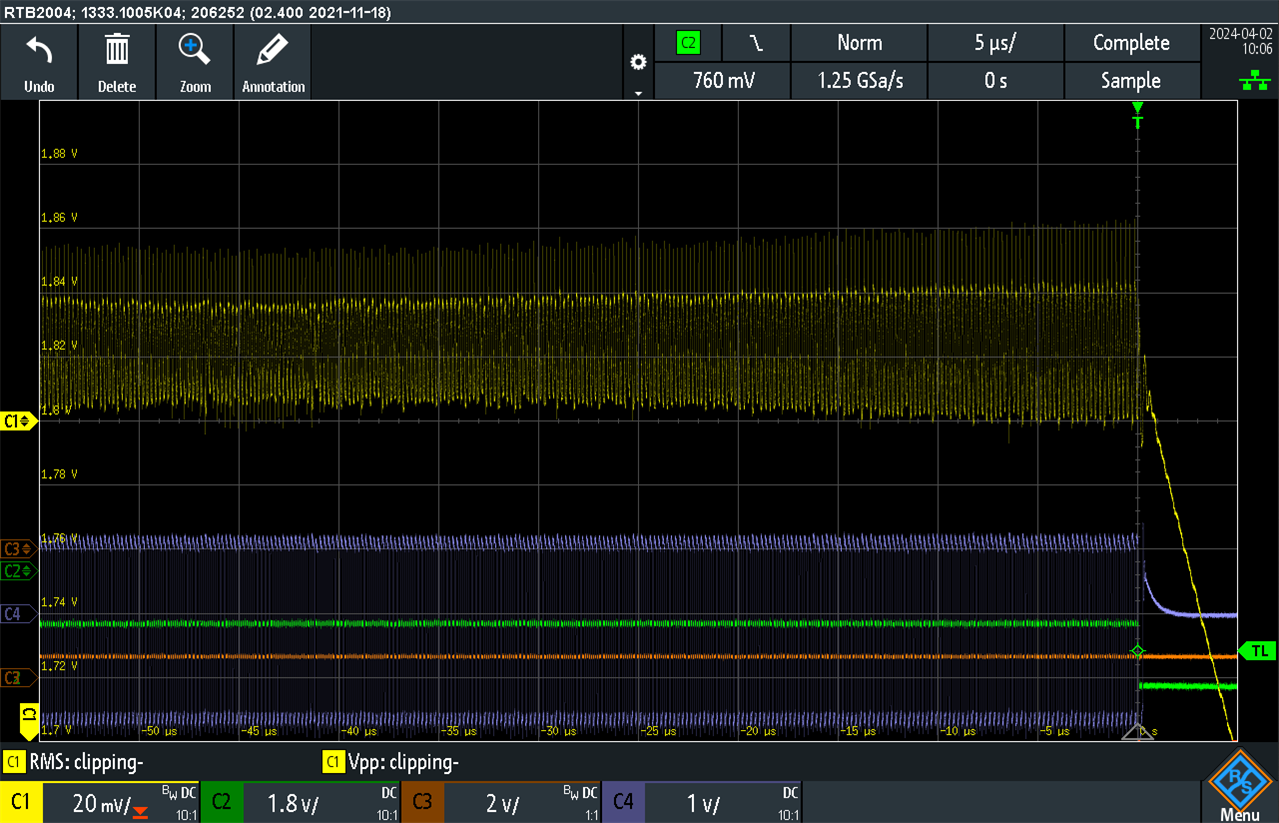

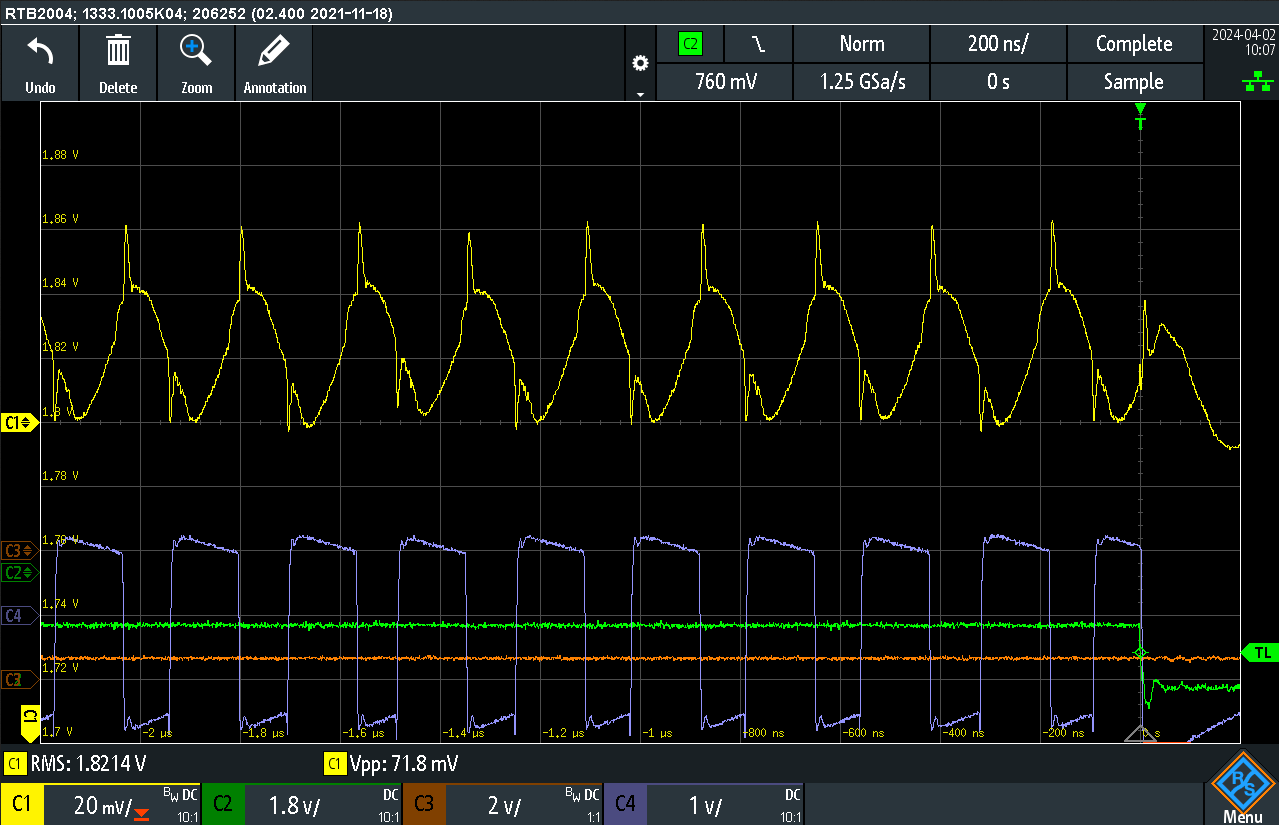

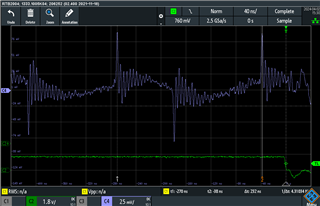

- Apply 2 A load using the external DC load - nRSTOUT is deasserted and PMIC is stuck in shutdown (see oscilloscope screen capture)

- Check PMIC status over I2C - TI PMIC-GUI can no longer detect the PMIC.

As we are not able to read out the system state after the failure/shutdown has occured, we have no information on what type of failure has occured and how to address the issue. We have access to a BOM-identical design that does not see these issues, as for the boards currently on hand some have this shutdown issue and some do not.

Things we've done to debug the issue so far:

- Checked incoming supplies - nothing obvious, looks stable when shutdown occurs.

- Added capacitance and adjusted feedback pin connection slightly - improves noise levels slightly, but shutdown behavior seem similar.

- Checked temperature dependence using cooling spray - no obvious change

- Removed all original load from the BUCk4-connected net and connected an adjustable DC load on the outer part of the PDN - able to reproduce the issue reliably.

- Checked incoming power good signals from external regulators - OK

Have you seen similar issues where the PMIC enters a shutdown state and stops communicating over i2c?