Hi,

I have a pack which consists of 6x LIFEPO4 cells in parralel, 4 in series.

The theorical capacity is 9000mAh, but actuel measurements with a battery cycler shows 8400mAh. We're using this lower value in the configuration of BqWizard.

The problem is that after a few cycle the FCC (Full Charge Capacity) drops to a level where the capacity is inconsistent with the real runtime. On some packs capacity goes the other way and is way too high to be consistent. I assume that this new capacity comes from the QMAX of each individual cells.

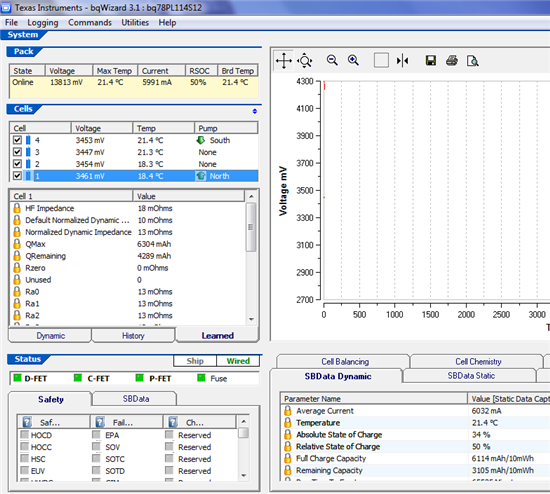

FCC is too low:

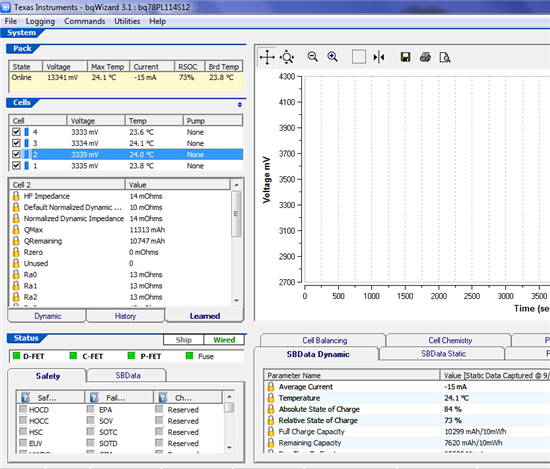

FCC is too high:

After a read of the TRM, I understand that QMAX is updated after the pack has been relaxed for long enough at two different qualified points. There is then a lookup of SOC vs OCV and then capacity of the cell is updated. We're using the right chemistry (405 for IFR13-EP1500, this is exactly what we have). I do not understand where this miscalculation comes from.

I would like to correct the event that triggers this miscalculation.

Included in this thread are the .csv dumped from "Save all parameters" from BqWizard. You have access to all the informations available to BqWizard.

7268.All parameters FCC low + FCC high.zip