Other Parts Discussed in Thread: UCC28C54

Hi

I have a WeBench related question regarding a design that WeBench made and how WeBench performs the calculation of turns ratio for a flyback transformer.

It concerns a design for the UCC28C54.

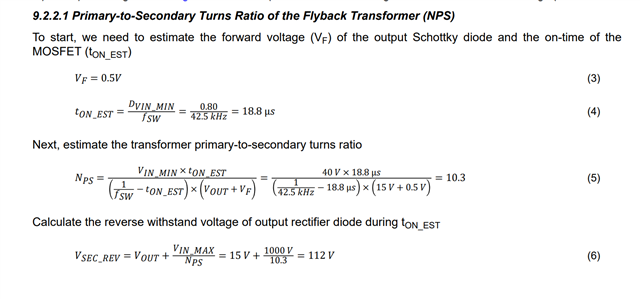

According to the data sheet, the primary to secondary turns ratio is calculated as

NPS = VIN_MIN × tON_EST / ( (1/fSW − tON_EST) × (VOUT + VF) )

Where tON_EST is given by

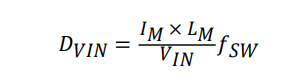

tON_EST = DVIN_MIN / fSW

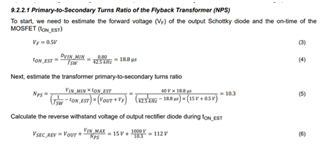

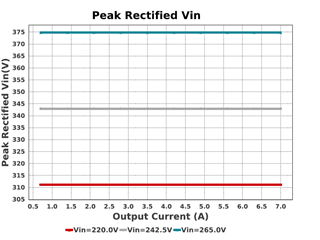

Now, the WeBench design gives the following data

DVIN_MIN = 37,291

fSW = 41.951 kHz

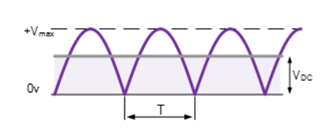

VIN_MIN = 311.124 V

VOUT = 12 V

VF = 1,05 V

Calculating for Nps with the data given from the WeBench design using the formulas in the datasheet, gives Nps = 14,2

BUT, thee WeBench design states Primary winding 119 turns and secondary winding 12 turns, which gives Nps = 9,9

Can you please explain this big difference?

I have attached the concerned WeBench design for reference.

Thanks, Thomas Nilsson