Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO, GPCRA0, GPCRB

Hi,

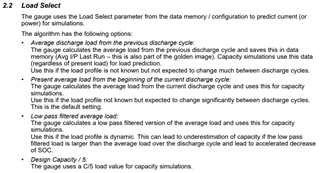

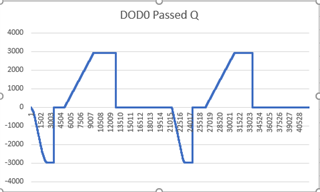

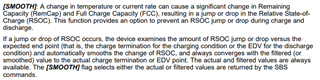

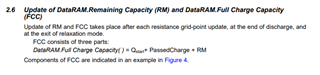

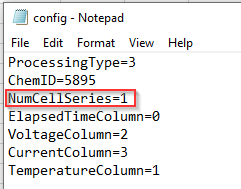

I followed the suggestion to set the load select to 1 and relearned it before conducting a charge and discharge test. My design capacity was 3000mAh, but during the charging process, I found that the fully charged FCC was still slightly lower by 300-400mAh. During the discharge process, I found that the battery SOC was also slightly lower by 300-400mAh when it reached 0% FCC update. However, at this time, the discharge did not reach the cutoff voltage of 2700mV that I set. When I continued to discharge to the cutoff voltage, I was able to release about 2900mAh of electricity. After the discharge was completed, the fully charged capacity was still slightly lower by standing for about 1 hour. After inserting the charger, the FCC was updated to around 2900mAh, but after being fully charged, the FCC update was still slightly lower by 300-400mAh. May I ask if this situation is a configuration error? Although it can discharge about 2900mAh of electricity, please help me solve it. Thank you!