Other Parts Discussed in Thread: UC2854B

Dear Sir,

We are developing a boost-PFC converter. For the generation of the switching pulses currently we are using the UCC28180.

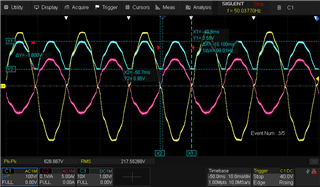

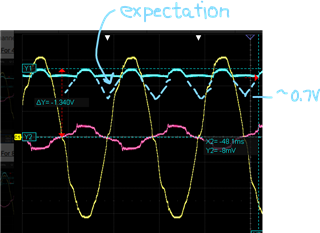

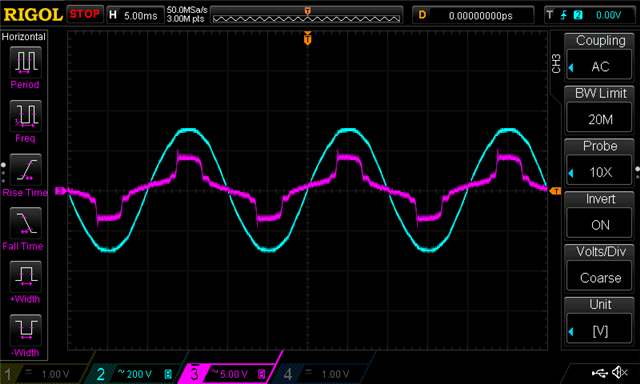

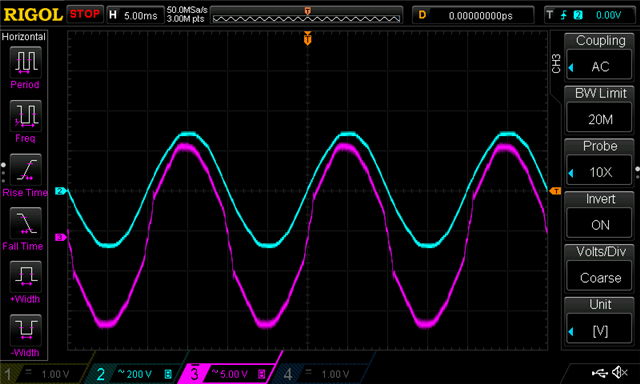

While experimenting for a power level of 1600W, we are getting distortion in the supply side current.

These distortion is getting worst in low power range.

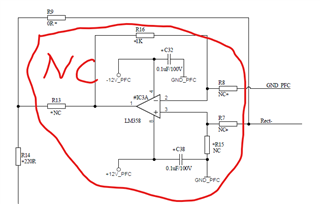

For your reference we are attaching the waveforms taken at the power level of 400W, 800W, and 1600W along with the PCB schematics.

PFC BOARD RND 0.00 SCH.pdf

PFC BOARD RND 0.00 SCH.pdf

The values for the Experimentations are as follows:

Supply Voltage = 230V,

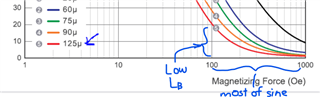

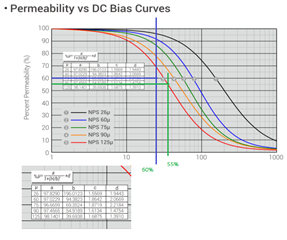

Boost Inductor = 350uH,

Output Capacitor = 14 * 150uF = 2100 uF.

R sence = 10 mohm.

Switching Frequency = 100 kHz.

Please go through our query and give us a possible solution to get better supply current THD and UPF operation.