Other Parts Discussed in Thread: UCC25640EVM-020, , PMP31164

Hi TI team

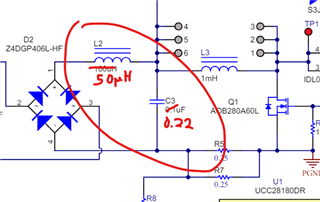

In UCC28180EVM-570 eval board we tried to load the eval board with UCC25640EVM-020 LLC eval board.

We are seeing a uneven waveform (positive cycle is different from negative cycle). Refer attached waveform.

We tried changing ICOMP capacitor value( thought of adjusting current loop) from 2700pF to 1000pF but there is no difference in current waveform.

We are seeing some ringing in the current waveform once after 70W output power ringing vanishnes but the uneven waveform (positive cycle is different from negative cycle) is observed.

Since positive cycle and negative cycle is different even harmonics are more and we could not able to meet DO-160G harmonic standard.

Please help us to get over this issue.