Other Parts Discussed in Thread: , INA226, LM5171

Hi TI-Team,

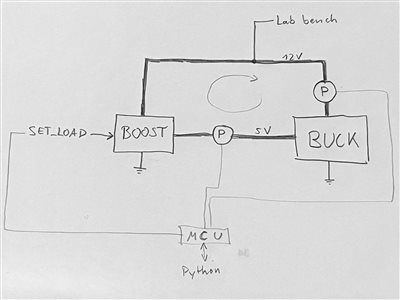

I am looking into using the LM5177 for our test setup, namely we are interested in recycling the power output of our Buck converter (our Device under test). We intend to use this IC in production too, hence possibly running a few hundred of these boards.

The buck's input is 12 V, the Buck output 5V or 3.3V, we hope to have a load of up to 18A, though 10-12A nominal.

- Is it possible to use LM5177 as an electronic load to set a load current on the Buck? Is it the most appropriate choice if we intend to sweep the power output of the buck converter, ideally automated by a microcontroller?

- Since we only need to boost the voltage, is it possible to omit the Buck-side MOSFETs and HB1 circuit completely and tie Vin directly to the sense resistor, or will the LM5177 not function properly if no devices are connected there? Would we need to connect SW1 in that regard?

Thank you for some clarification!

best regards,

Karim

PS: Just saw the LM51772 but it isn't available anywhere..