Dear,

We must have a negative power supply of -15V.

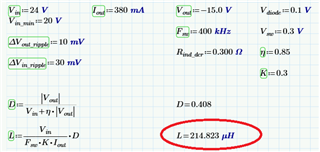

The load is between 250 and 450mA with an input voltage of 24V.

The input voltage can be variering between 20 and 30V.

The switching freq is 400Khz

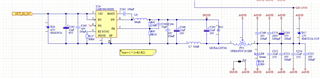

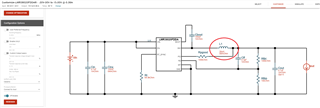

The design is based on the application note snva856b: https://www.ti.com/lit/pdf/snva856

At first can we using the LM38020 as an inverting convertor?

So not, which regulator we can use than?

So, yes

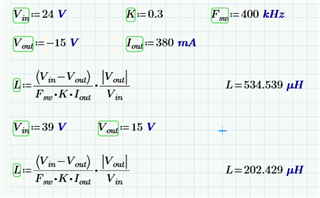

The calculation of the inductor is around the 200µH follow the application note.

If we use this value we will blow up the regulator due to over temperature.

what could be the reason for this?

Only when we reduce the inductance to 56 or 68µH it works better, but the regulator is still quite hot (70°C).

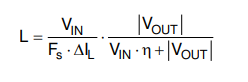

How we should calculate than the inductor value?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.