Other Parts Discussed in Thread: LM5185, LMQ66420, LMQ66430, LMR36520

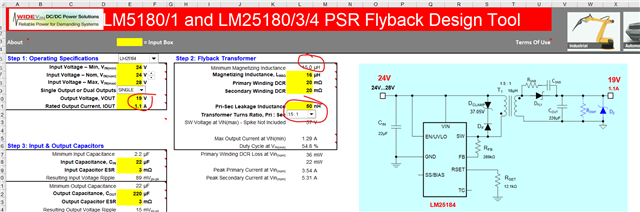

This post is related to an earlier post “LM25184: Flyback eval board output loses regulation”. I am using eval board LM25184EVM-S12. My goal is VDC-in = 24V, VDC-out = 24, IDC-out = 1 A. I made the modifications required from the related post but was losing output regulation during low power heat runs. It was then recommended that I increase the inductance of the transformer from 7.5 uh up to greater than 13uh. The one I wound measures 14.5 uh and .31 uh leakage.

I am able to get to 24V-out and have successfully increased the output current in steps up to .642 A so far. The problem I am having is this. At these higher output current levels, when I turn on the DC supply (BK #1610), the DC supply goes into output current limit and clamps the supply voltage, so the eval board cannot start. Why is the input current draw so high (over an amp)? Is that normal? Here is my last data. For me to be able to run at this level I had to bring in a partial load so that it started and then parallel the load resistance with enough resistance (while running) to get to the current level I was testing for.

Vout = 24 V

RL = 37.4 ohm

Iout = .642 A

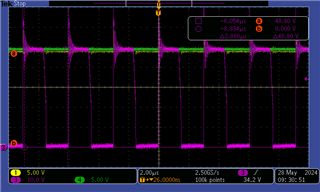

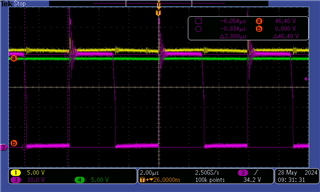

F = 223.21 kHz, Duty Cycle .504

Idc-in = .808

Pdc-in = 19.4 W

Eff = .794

What level of input current from the 24VDC supply can I expect to see while starting into a 1 A output load? Also, the surface temperatures during the heat run (1 hour) were as follows. Are these expected to be this high? Is there something I can do to or change to reduce this?

LM25184 = 117 F,

D2 (3SMAJ5938B) = 149 F,

D1 (SS30100HE_R1_00001) = 114 F

Thank you - John