Tool/software:

Hi,

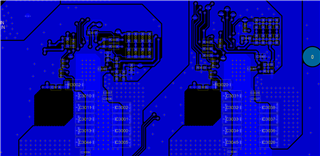

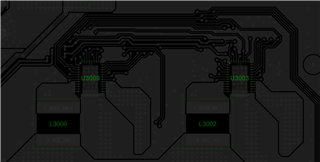

I've designed a 2-phase D24A based buck converter to get 1V2 60A output out of 12V input. I've used TPS546D24AEVM-2PH schematic. Changed the coils to 2 x 1uH, and a VSET resistor to ground to move from 0V8 to 1V2. Rest ir pretty much the same. Board is 4 layer as that should basically be more than enough to the project.

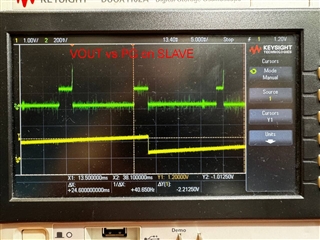

Supplied 12V. What is happening after powering up is that the bucks are buzzing. The output signal is a kind of a sawtooth going form 0,3V up to about 1,4V. I observed that when output voltage crosses 1V2 it pulls the PG on the SLAVE high. On the master the PG signal remains always 0.

There is shourly some communication on BCX lines as well as on SYNC line.

I checked every bit of the design and compared against the reference design. Did not find anything critical that might seem to couse that kind of strange behaviour.

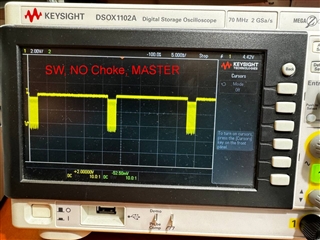

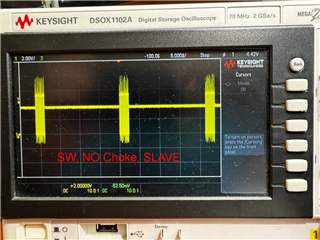

Just out of curiosity I desoldered both chokes to measure SW signal on both devices. Suprisingly they are somehow different.

On Master the SW signal oscillates around 4V and going from aprox -1V to +8V. While for the slave device it would also go with 4V line with the osccilations but ranging only form -1V to +3,8V. I have no idea why is there any difference - FYI as an observation.

Suspected bad soledering altgough just for the sake of testing that I swapped the IC however the result was the same. That's not the case than. Had build second sample of the board - Same result also though.

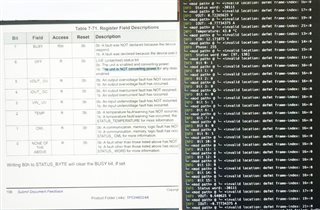

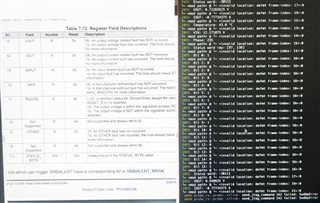

I did not connected it via PM-BUS yet so cannot read error flags at the moment - Waiting for my colegue to code that for me.

Schematic:

Oscilloscope measures:

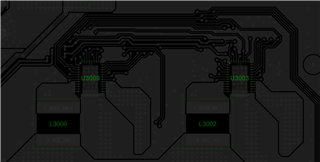

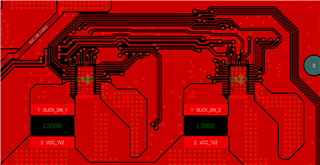

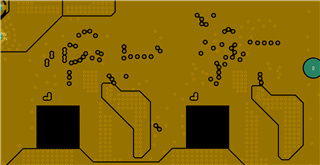

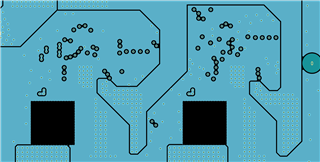

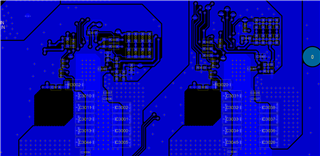

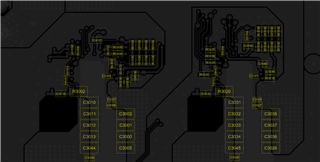

Layout: