Other Parts Discussed in Thread: TPS775, TPS767

Tool/software:

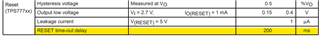

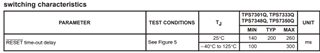

Would you let me know about Min and Max value for RESET time-out delay?

Datasheet is described only Typ value: 200ms.

Best regards,

Satoshi

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi Satoshi,

Unfortunately this device is quite old and we no longer have access to the design database, and the documentation is very limited. I found a characterization report, but it does not appear that the RESET time-out delay was characterized; the 200us (typ) spec is probably just from the design.

Regards,

Nick

Hi Nick,

Thank you for quick reply,.

For reference, the TPS73xx has a Min: 100ms and a Max: 300ms, but won't the TPS777 have a similar range?

Does the Min to Max range vary depending on the device?

One customer needs Min to Max information, and requests that it's okay if it's just a reference value.

Best regards,

Satoshi

Hi Satoshi,

TPS73xx is a different family, so the specs are likely different. The closest devices to the TPS777 in regards to die design are the TPS767 and TPS775, but it's the same story with these devices - no design information and no characterization data for the RESET time-out delay. Unfortunately there's nothing we can do to provide this data without significant effort since the data would have to be collected on the bench.

Regards,

Nick

Hi Nick

Thank you for reply,

I understood your situation.

Since these are parts that are currently being produced, customer believe that the numbers are specified by methods such as sampling during shipping inspection to determine whether these are OK or not.

Would you just tell me in which range the pass/fail judgment falls?

If it is difficult to disclose, would you just let me know if 140 to 260ms or 100 to 300ms is OK?

Best regards,

Satoshi

Hi Satoshi,

Since these are parts that are currently being produced, customer believe that the numbers are specified by methods such as sampling during shipping inspection to determine whether these are OK or not.

This is only true of specs that have min/max values. Specs that only have typical values are not tested before shipping.

Would you just tell me in which range the pass/fail judgment falls?

There will not be a test written into the test program since there is not a min/max spec, so providing the range is not possible.

If it is difficult to disclose, would you just let me know if 140 to 260ms or 100 to 300ms is OK?

There is no data that we have to indicate a range of possible times.100ms to 300ms is probably reasonable, but since we have no data to back that up we can't guarantee anything.

Regards,

Nick