Tool/software:

Two questions on the duty cycle clamp:

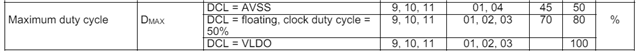

- The datasheet mentions that for the 75% duty cycle clamp (DCL floating) the clamp value may vary based on duty cycle of the external clock. Can you please clarify that relationship? For instance if I pass in a 45% duty cycle clock does the duty cycle clamp value vary by 5%? And does this variation always occur or must certain operational or environmental conditions be met for this to happen?

- Do the dead times between primary and SR have any effect on the duty cycle clamp value? (Presumably if they do not then the dead time would count against SR ON time)