Other Parts Discussed in Thread: TPS25750, , BQ25756

Tool/software:

I have a prototype PCB with TPS25750 and BQ25792 charger.

Battery is 3S and charging current is 2A.

The BQ gets quite hot and stop charging after just 10 seconds. I tried placing heatsinks etc on it but no avail.

In the first iteration of the board, I had no ground polygon pours around the device in top or bottom layer. the inner layers had ground pours. the SW nodes had similar pours as in EVB.

In the second iteration of the board, I have placed many suitably sized vias for heat dissipation and I wanted to be sure before manufacturing.

Since the board is part of an embedded device, How can I ensure proper heat dissipation besides more plane area around the BQ? if any other part is recommended, pl let me know.

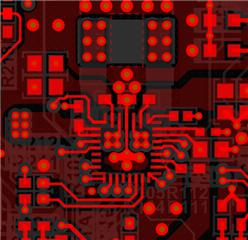

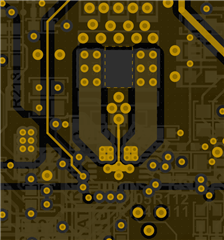

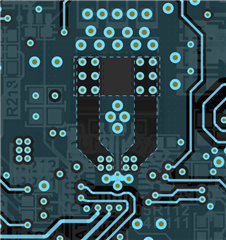

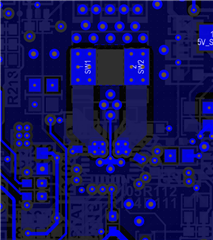

I am attaching the pictures for layers 1, 3, 4, 6. 2 and 5 are ground planes.

Layer 1:

Layer 3:

Layer 4:

Layer 6:

Lastly, how can we estimate heat dissipation for the BQ?