Other Parts Discussed in Thread: GPCRB

Tool/software:

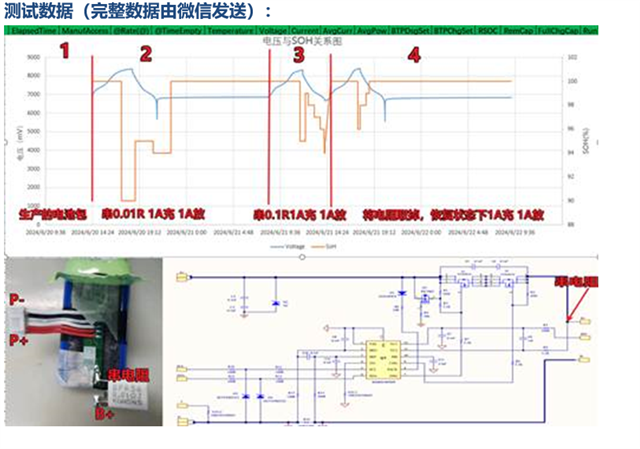

Supplement the entire testing process and total data as follows:

testing procedure

| Health verification of room temperature resistance value | Sample: 1 piece Instrument: Lithium battery secondary charging and discharging equipment 1. Charge the empty battery at 1ACC to full charge voltage and 0.02CCV to full charge Pressure. If the sample has already been prepared from the battery supplier, it can be directly tested. 2. Record the initial value of SOH (SOH1) 3. Connect a 0.01 ohm resistor in series to the PACK and perform a full charge to full discharge before discharging Record the SOH value (SOH2) during the electrical process 4. Connect a 0.1 ohm resistor to the PACK and perform a full charge to full discharge before discharging |

1.SOH1>SOH2>SOH3 2. SOH has no jump during a single discharge process |

Test data (complete data will be attached later):

Question for Testing: It appears that SOH can fluctuate significantly under many conditions, even if the cell is equipped with a resistor (simulating an increase in internal resistance of 100 milliohms), SOH may still recover to 100%, making it unclear how to use this important indicator in the field and even questioning its accuracy. This has also raised questions about the significance of introducing a capacity meter. Question 1: Since customers are unable to know the SOH change, please provide a SOH range limit for us to use for battery health warning. Yellow means we will send a message to customers every day saying the battery needs to be replaced. Red means it is not allowed to use. Please provide a suggested percentage for these percentages (can be divided by temperature, voltage, or whether it is read during charging or discharging, or other ways, based on TI's recommendations. Newland software can handle this). Low temperature: 15°C or below SOH yellow warning % SOH red warning %: Normal temperature: 15°C to 40°C SOH yellow warning % SOH red warning %: High temperature: 40°C or above SOH yellow warning % SOH red warning %: Question 2: In addition, please provide information based on the actual usage of your other customers. If we can collect information from the power meter (voltage, current, temperature, and all registers in the power meter) through the network, which information would you need to remotely assess the battery condition? Currently, we have designed the following, please let us know if there is any additional or omitted information:

Finally, the supplementary data is as follows:

Comprehensive Data Chart of SOH Changes in 100 Cell String Resistance Test.xlsx